Eight Steps Toward Improving Construction Productivity

Partnering and collaboration must be a key performance metric by which real property owners and facility management professionals are measured. Until this occurs, there is little hope for construction sector productivity improvement.

- Owners Foster and Mandate Collaborative Construction

- Best Value versus Lowest Bidder Procurement

- Full Financial Transparency

- Shared Risk / Reward

- Mutual Goals & Trust

- Common Terms, Definitions, and Data Architectures

- Continuous Education, Improvement and Monitoring

- Adoption of LEAN Alternative Construction Delivery Methods – Job Order Contracting, JOC & Integrated Project Delivery (IPD)

BIM has stagnated, and the construction industry (Architecture, Engineering, Construction, Operations, and Real Property Owners) as a whole remains unproductive due lack of focus upon process change management.

While most of us are aware that early and ongoing communication among all renovation, repair, or new construction stakeholders is the path to success, its rare that a team is established that is both clear on objectives and working towards common objectives.

Successful outcomes should be the objectives of ALL participants and partnering must not only be encouraged but mandated by real property owners.

Partnering is can not be accomplished solely through the implementation of technology. Nor is excessive management and control the path to success. Adopting and fostering of LEAN best management practices, specifically developed for construction and which focus upon outcomes, is the path to productivity improvement.

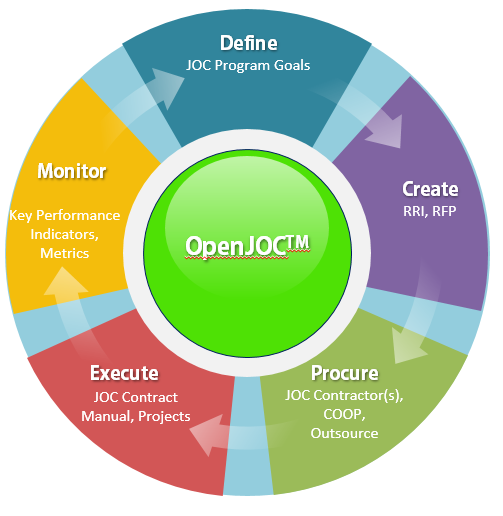

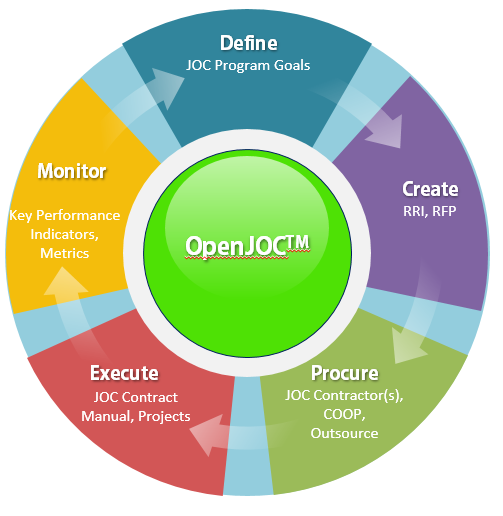

Job order contracting and integrated project delivery are two examples of LEAN construction delivery methods that share decades of successful implementation and enable higher quality and a higher percentage of projects to be completed on-time and on-budget.

The most important element to successful project delivery is an educated and capable Owner. An Owner that understands collaborative construction delivery and is focused upon successful outcomes for ALL project participants and stakeholders.

Technology will do little to solving the construction industry’s productivity issues. Despite the marketing of software vendors, technology is simply an enabler for faster and lower cost consistent deployment. The key to success is the best management practices and processes embedded within technology.

Real property owners required training and ongoing professional development. This includes real property executives, facility management, technical/engineering teams, cost estimators, purchasing/procurement, and facility users. Educational institutions must also alter their programs. Examples of competencies and content include; life-cycle management of the built environment, total cost of ownership practices, LEAN best management practices, and collaborative and/or alternative construction delivery methods.

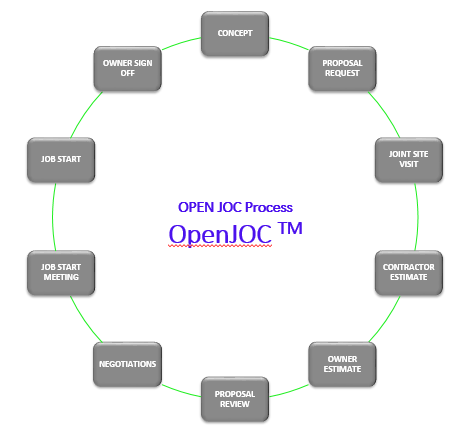

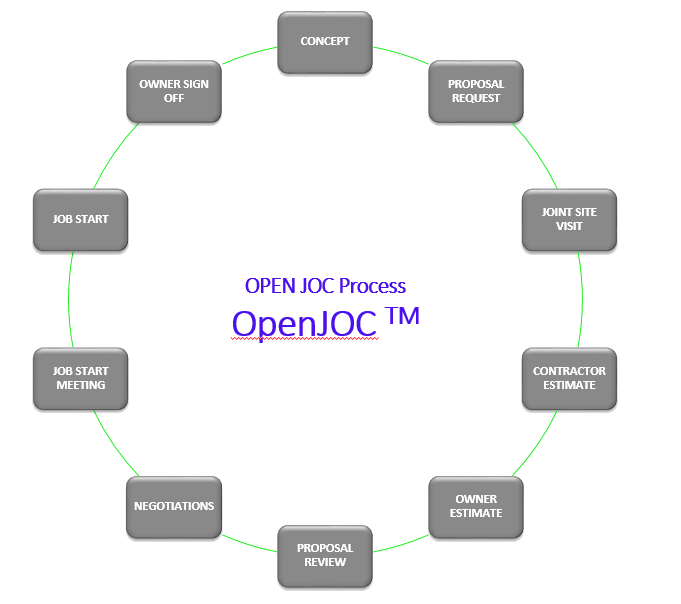

Mandatory Partnering

While mandatory partnering may seem contradictory, it is not. All construction contracts, projects, and programs should include a operational manual. The manual describes the roles, responsibilities, deliverables, and outcomes for all parties. While each manual can, and should be tailored to each owner’s requirements, common components of the core framework are ever present. The operations manual spells out all requirements, terms, etc., associated with the collaborative construction delivery process. An example of a job order contracting process is shown below.

Common elements to any LEAN Collaborative Construction Delivery Method

Common elements to implementing a productive LEAN construction delivery methods include the following:

Owner Leadership of Team Collaboration

Best Value Procurement

Mutually Beneficial Goals and Outcomes

Performance-based Reward System

Shared Risk/Reward

Common Terms, Definitions, and Data Archtectures

Outcome-based Key Performance Metrics – KPIs

Continuous Monitoring, Improvement, and Education/Training

Global Oversight with Local Implementation

” Great care is taken to establish an IPD team where participants can work together as a collaborative unit. Team formation considers capability, team dynamics, compatibility, communication, trust building and commitment to an integrated process….Once a team is formed, it’s important to create a team atmosphere where collaboration and open communication can flourish.” – AIA

One of the most important life lesson that I have learned is that success or failure is generally not determined by a problem, issue, or even an opportunity, but rather by how we react and deal with the situation. Whether it’s a construction project, or other situation, if we react and act as a team versus as individuals, outcomes are ultimately improved.

“The goal of everyone in the industry should be better, faster, more capable project delivery created by fully integrated, collaborative teams. Owners must be the ones to drive this change, by leading the creation or collaborative, cross-functional teams comprised of design, construction, and facility management professionals.” – CURT