Asset Lifecycle Model

for

Facility / Infrastructure Total Cost of Ownership Management

Framework, Glossary & Definitions

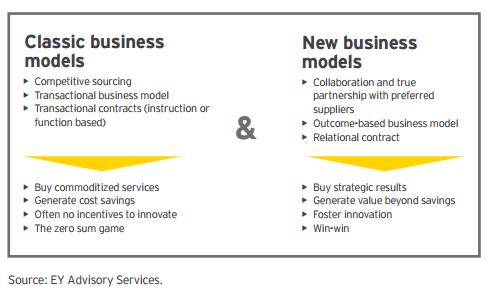

- Life-cycle versus first-cost perspective

- Value-based procurement

- Outcome-focused LEAN management

- Collaborative construction delivery – Job Order Contracting, JOC and Integrated Project Delivery

- Common terms, definitions, and standardized data architectures

- Preventative versus reactive maintenance

- Data-driven decision support

- Key performance indicators – KPIs

The consistent use outcome-focused and best value based LEAN collaborative business practices deliver robust, scalable and repeatable processes to drive efficient life-cycle management of the built environment and associated renovation, repair, maintenance, sustainability, and new construction.

Collaboration, transparency, mutual respect, and common terminology enable effective communication among the various decision makers, building managers, operators and technicians involved with facilities and physical infrastructure investment and management.

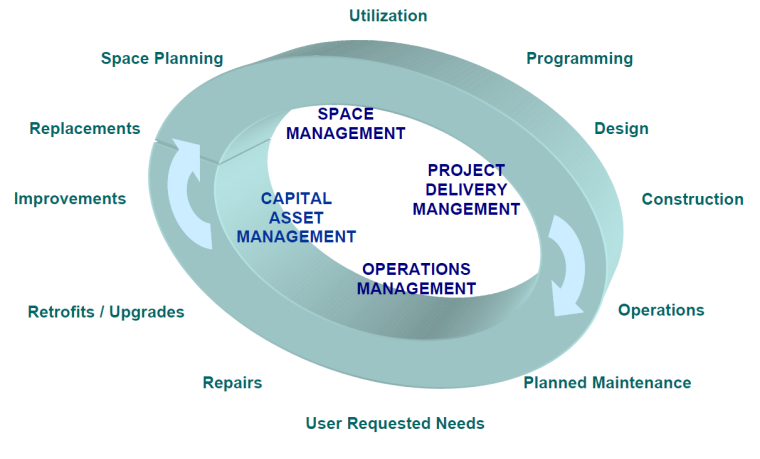

Activities that occur over the lifetime of a physical asset – programming, design, construction, operations, maintenance, repairs and utilization – and there are requisite core skills or COMPETENCIES to perform these activities. Owner must become better educated in order to perform in their role as stewards of the built environment.

These competencies are aligned with multiple specialized asset management business processes and practices. The level of collaborative leverage of Competencies and Asset Management Business Processes and Practices determines of effectively an asset’s life-cycle will be managed.

INDUSTRY: SPACE MANAGEMENT

Competency: Space Planning, Utilization

Metrics/Cost Models

Annualized Total Cost of Ownership (TCO) per building per gross area = Rate per square foot

Annualized TCO per building/Current replacement value = Percent of Current Replacement Value (CRV)

Annualized TCO per building/Net assignable square feet = Cost rate per net assignable square

feet per building

Annualized TCO per building/Non-assignable square feet = Cost rate per non-assignable square

feet per building

Annualized TCO per building/Building Interior square feet = Cost rate per interior square foot per

building

Churn Rate

Utilization Rate

Adequate Facility/Structure/Space

A facility/structure/space that is fully capable of supporting its current use without modification or repairs (beyond currently funded routine maintenance) and has an acceptable level of reliability.

Alteration

Work required to adjust interior arrangements or other physical characteristics of an existing facility/structure so that it may be more effectively adapted to or utilized for a new or changed use.

Assignable Square Feet

A term used to describe areas that may be occupied and is acceptable for a designated purpose or function. It does not include walls, stairways, corridors, restrooms, parking facilities or mechanical space.

Area/Gross Square Footage (GSF)

A unit of measure representing the cumulative total of an organization’s building(s) inclusive of all floors to the outside faces of exterior walls. Defined as the sum of the floor areas on all levels of a building that are totally enclosed within the building. Measure exterior building gross area to the outside face of exterior walls, disregarding canopies, cornices, pilasters, balconies and buttresses that extend beyond

the wall face and courtyards that are enclosed by walls but have no roof. The building exterior gross area of basement space includes the area measured to the outside face of basement or foundation walls. Exterior bridges and tunnels that are totally enclosed, constructed areas connecting two or more buildings are included in building exterior gross area. This measurement indicates total constructed space and is useful for building efficiency and construction cost comparisons. (Source: ASTM E 1836-01)

Building Core and Service Area

Defined as the floor area of a facility, which is necessary for the operation of the facility and is not available for general occupancy. This may include the following: building lobbies, mechanical rooms, electrical rooms, telephone (communications) rooms, restrooms, custodial rooms, loading docks and utility tunnels that are not used for any other purpose. (Source: ASTM E 1836-01)

Building Projections

A convector, baseboard heating unit, radiator, or other building element located in the interior of a building adjacent to a wall that prevents the use of that space for furniture, equipment, circulation or other functions. (Source: ASTM E 1836-01)

Box Move

No furniture moved, no new wiring or telecommunication systems required. Files and supplies moved. (Source: Project Management Benchmarks, IFMA © 2002)

Bullpen Style Offices

Open office areas with no partitions. (Source: Project Management Benchmarks, IFMA © 2002)

Churn Rate

The total number of moves made within a 12-month period of time divided by the number of occupants during the same period. (Source: Project Management Benchmarks, IFMA © 2002)

Common Support Areas

Facility assignable area includes the area devoted to common support services. Common support area is the portion of the facility usable area not attributed to any one occupant but provides support for several or all occupant groups. Examples of common support areas are: cafeterias, vending areas, auditoriums, fitness facilities, building mail rooms and first aid rooms. These may be separately identified as a sub-category of facility assignable area if required. (Source: ASTM E 1836-01)

Construction Move

New walls, new or additional wiring, new telecommunication systems or other construction needed to complete the move. (Source: Project Management Benchmarks, IFMA © 2002)

Excluded Area

Fully enclosed spaces with adequate clear headroom that are not intended for, or are not suitable for occupancy by people or equipment, but not spaces that are temporarily unusable due to flood, fire damage, construction or renovation activity. (Source: ASTM E 1836-01)

Exterior Walls

Defined as the width of the walls as measured at the intersection of the plane of the finished floor and the finished interior surface of the walls. (Source: ASTM E 1836-01)

Facility Assignable Area

Calculated by measuring the portions of the floor used to house personnel, furniture, support areas and common support areas. Each assignable area is measured to the outside of the enclosing wall or furniture panel except in the case where a wall or furniture panel is common to more than one assignable area. In this case measurements are taken to the center of the wall or furniture panel. This measurement is useful for detailed programming, planning, allocating and layout of space. (Source:

ASTM E 1836-01)

Facility Interior Gross Area

Defined as the building exterior minus the thickness of the exterior walls. (Source: ASTM E 1836-01)

Facility Rentable Area

Calculated by subtracting major vertical penetrations, interior parking space and void areas from facility

interior gross area. (Source: ASTM E 1836-01)

Facility Usable Area

Calculated by subtracting the primary circulation and the building core and service areas from the facility rentable area. It is area that can be assigned to occupant groups. This measurement is useful for programming, planning and allocating space. (Source: ASTM E 1836-01)

Finished Surface

A wall, ceiling or floor surface (including glass) as prepared for tenant or occupant use. Excluding the thickness of any special surfacing materials such as paneling, furring strips and carpet. (Source: ASTM E 1836-01)

Furniture Move

Reconfiguration of existing furniture and/or furniture moved or purchased. Minimal telecommunication reconfiguration needed. (Source: Project Management Benchmarks, IFMA © 2002)

Interior Parking Space

Defined as space used for vehicular parking space that is totally enclosed within the (occupied) building envelope. (Source: ASTM E 1836-01)

Interstitial Area

The area of load-bearing surfaces, located above or below occupied building floors that are not available for general occupancy due to inadequate clear headroom, but may contain building mechanical or electrical systems predominantly serving adjacent floors or provide access to such systems. (Source: ASTM E 1836-01)

Major Vertical Penetrations

Includes stairs, elevator shafts, utility tunnels, flues, pipe shafts, vertical ducts and their enclosing walls.

(Source: ASTM E 1836-01)

Open Plan Offices

Office spaces divided by movable partitions. (Source: Project Management Benchmarks, IFMA © 2002)

Primary Circulation

Defined as the portion of a building that is a public corridor or lobby. Further defined as space required for access by all occupants on a floor to stairs, elevators, restrooms and building entrances or tenant space entry points on multi-tenant floors. (Source: ASTM E 1836-01)

Private Office

Enclosed office, enclosed floor to ceiling walls. (Source: Project Management Benchmarks, IFMA © 2002)

Secondary Circulation

Defined as the portion of a building or floor required for access to some subdivision of space that is not defined as primary circulation. Secondary circulation may or may not be surrounded by walls or furniture panels. (Source: ASTM E 1836-01)

Space Planning

Space Planning is the process of analyzing current and future requirements relative to physical assets (i.e., type, condition, size, capacity, with respect to their ability to support and advance programs and activities at a level deemed appropriate by appropriate parties in concert with associated regulations, codes, mandates, and acceptable levels of performance). Space planning typically involves identifying

each distinct type of activity covered by the program and defining the appropriate values relative to size, capacity, utilization rates, etc.

Swing Space

Temporary space dedicated to displaced workers until permanent space is finished. (Source: Project Management Benchmarks, IFMA © 2002)

Utilization Rate

An indicator used to determine how efficiently available space is being used. Usually time-based in terms of month, quarter or year.

Utilization Rate = Occupied Space

Facility Usable Area

Void Areas

Defined as rooms that are more than one story in height. Void areas exist on upper floors such as atriums, light wells or lobbies. (Source: ASTM E 1836-01)

Workstation

Defined as any type of space designated for occupant usage (either open or enclosed area), where an

occupant can be seated. (Source: Project Management Benchmarks, IFMA © 2002)

INDUSTRY: SPACE MANAGEMENT

Competency: Programming

Metrics/Cost Models

AI (Adaptation Index) or PI (Programmatic Index) = PR (Program Requirements)

CRV (Current Replacement Value)

Uptime or Downtime – Defined in percent, as amount of time asset is suitable for the program(s) served.

Adaptation Index or Adequacy Index (AI) or Programmatic Index (PI)

A comparative inter/intra sector metric/benchmark expressed a value from 0.0 to 1.0 that indicate the program/mission-based condition of a facility. AI is calculated by dividing the total value of deferred physical programmatic/adaptive requirements (PR) by the current replacement value (CRV) (i.e. AI=PR/CRV).

Program-based or programmatic requirements are facilities-specific needs that are established to meet the mission of the facility or organization, inclusive of evolving technological, programmatic or regulatory demands.

Taking an educational science laboratory as an example, while an existing lab may have zero physical deficiencies the configuration and equipment (e.g. fume hoods, lighting, computer networks, etc.) may not be suitable for current teaching methods. All of the physical, program-related needs therefore have a cost to remedy, and are considered as programmatic deficiencies. Similar to physical deferred maintenance, deferred programmatic requirements are those current needs that are not funded in the present fiscal year. Additionally, the facilities-specific programmatic requirements may include items such as space, configuration, adjacency, security, etc.

Adequate Facility/Structure/Space

A facility/structure/space that is fully capable of supporting its current use without modification or repairs (beyond currently funded routine maintenance), and has an acceptable level of reliability.

Alteration

Work required to adjust interior arrangements or other physical characteristics of an existing facility/structure so that it may be more effectively adapted to or utilized for a new or changed use.

Assignable Square Feet

A term used to describe areas that may be occupied and is acceptable for a designated purpose or function. It does not include walls, stairways, corridors, restrooms, parking facilities or mechanical space.

Facility Usable Area

Calculated by subtracting the primary circulation and the building core and service areas from the facility rentable area. It is area that can be assigned to occupant groups. This measurement is useful for programming, planning and allocating space. (Source: ASTM E 1836-01)

Programming

Programming is the process of planning and organizing the quantitative physical requirements of resources needed to accomplish established goals. A program is an organized set of activities directed toward a common purpose or goal undertaken or proposed in support of an assigned area. A program is characterized by a strategy for accomplishing a definite objective(s), which identifies the means of accomplishment,

particularly in quantitative terms, with respect to manpower, materials, and facilities requirements. A program normally includes an element of ongoing activity and is typically comprised of technology-based activities,

projects, and supports an established level of reliability.

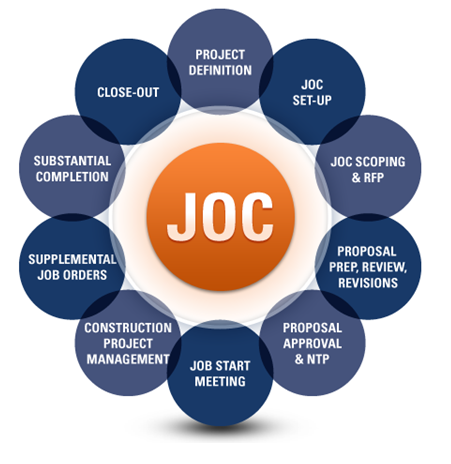

INDUSTRY: PROJECT DELIVERY

Competency: Design, Construction

Metrics / Cost Models

Estimating Index (Source: SAM Initiative, APPA 2003)

Delivery Speed, Cost Rate of Facility to Completion, Dollar per square foot per month (Source:

Selecting Project Delivery Systems, Sanudio/Konchar, 1999)

Project Soft Cost Index (Source: SAM Initiative, APPA 2003)

Total Cost (inclusive of construction, design, project management, etc.)/square foot vs. Regionalized Applicable Standard Reference Cost, Percent Variance

Architecture and Engineering Costs

All actual/projected costs charged by the architecture and engineering firms to a project. Total actual project costs represent the total actual cost to complete and close a project.

Construction

Any combination of engineering, procurement, erection, installation, assembly or fabrication activities involved

to create a new facility/structure or to alter, add to, or rehabilitates an existing facility/structure, and its support areas such as parking, grounds, roadways, service buildings for power generation, waste disposal, etc., and the costs to construct interior spaces including the costs of ceilings, lighting, life safety such as sprinklers,

heating, ventilation, air conditioning, floor systems, carpeting, walls, doors, hardware and special finishes.

Design

Design begins with and is the analysis, understanding and response to the base of data, intentions, and impressions collected in the process of discovering what there is to know about a project. The combination of all this into a unified solution is the synthesis that is the core of design.

Estimating Index

The purpose of the estimating index is to measure the accuracy and credibility of the estimate as compared to actual work accomplished. The index is usually used for measuring performance for projects or reimbursable work orders. Different size projects may be accomplished so differently that they may be grouped into several

categories with an estimating index calculated for each. Deviations outside of a reasonable range of values should be examined for opportunities to learn and improve the estimating process. The use of this indicator should also encourage field personnel to be innovative in reducing actual time and costs. As with any cycle of improvement, consistent performance above or below 1.00 will indicate that the estimates are no longer credible and that the estimates need to be adjusted to reflect the actual level of productivity. The estimating index is the ratio of actual time or costs to do work divided by estimated time or costs. The unit of measurement should be the same for both actual and estimated. Time is usually measured in days and costs

are usually measured in whole dollars. When measuring the average performance over a period of time, such as monthly, the number of samples can vary so long as they contain a representative mix to provide reasonable accuracy. The index is usually represented as a decimal number. The estimating index will be greater than 1.00 when the actual time or costs exceeds the estimate. Similarly, the estimating index will be

less than 1.00 when the actual time or costs is less than the estimate.

Estimating Index = Actual Time or Costs

Estimated Time or Costs

(Source: SAM Initiative: APPA 2003)

Project Soft Cost Index

The purpose of this performance indicator is to determine the relative percentage of soft costs in a project. A smaller percentage implies a more efficient use of project funds. The performance indicator can be used to determine how efficiently project funds are utilized for individual projects or to trend cumulative results and

variances for numerous projects over time. These costs are related to those items in a project that are necessary to prepare and complete the non-construction needs of the project. Soft costs include such items as architecture, design, engineering, permits, inspections, consultants, environmental studies and regulatory

demands needing approval before construction begins. Soft costs do not include construction, telecommunications, furnishings, fixed equipment and expenditures for any other permanent components of

the project.

Project Soft Cost Index = Soft Costs

Adjusted Total Actual Project Cost

(Source: SAM Initiative: APPA 2003)

Construction Management At-Risk

Defining Characteristics:

• Separate contracts for design and construction.

• Final selection of builder is based on any combination of Total Construction Costs and other criteria.

Available Selection Options:

• Qualifications Based Selection.

• Best Value Bid.

Typical Characteristics:

• Builder selection occurs during design.

• Builder selection based on a “qualifications based selection” (that may or may not include fees and/or general conditions).

• Builder provides a cost guarantee Guaranteed Maximum Price (GMP) and a schedule guarantee either

during or after their final selection.

• Builder is able to provide input such as cost, schedule and constructability during design.

• Overlapping of design and construction phases (fast-tracking) of the project is typical.

• Cost guarantee provided in the form of a not-to-exceed Guaranteed Maximum Price (GMP).

• Selection of designer and builder are independent processes.

Note: For each of the project delivery methods found below, Design-Build, Design-Bid-Build, and Construction Management At- Risk, the method’s “defining” characteristics, the available selection options (based on definitions provided) and a few sample “typical” characteristics of each method are provided for clarification purposes.

“Defining Characteristics” – Prescribe a delivery method and uniquely distinguish a delivery method from the other delivery methods.

Available Selection Options (definitions):

• Low Bid – Builder’s final selection based 100% on lowest Total Cost and no other criterion.

• Best Value Bid – Builder’s final selection based on some weighting of the Total Cost and other criterion such as

qualifications.

• Qualifications Based Selection – Total Construction Cost not a factor in the builder’s final selection. The final selection of the builder is based on either:

o Pure qualifications based selection (qualifications only, no element of price) or

o A combination of qualifications and fees (possibly including general conditions).

“Typical Characteristics” – Typical characteristics may be “typical” characteristics of a delivery method, but are not required to define the delivery method.

Design/Bid/Build

Defining Characteristics:

• Separate contracts for design and construction.

• Final selection of builder is based usual on Total Construction Cost.

Available Selection Options:

• Low Bid Only (based on the “defining characteristics”).

• Best Value.

Typical Characteristics:

• Design is typically near 100% complete at time of final builder selection.

• The construction phase follows the design phase (after bid process) in linear fashion.

• Selection of designer and builder are independent processes.

Design/Build

Defining Characteristics

• A single contract for design and construction.

Available Selection Options:

• Qualifications Based Selection.

• Best Value Bid.

• Low Bid.

Typical Characteristics:

• Design-Builder able to provide input such as cost, schedule and constructability during design.

• Overlapping of design and construction phases (fast-tracking) of the project.

• Cost guarantee provided in the form of a not-to-exceed Guaranteed Maximum Price (GMP).

INDUSTRY: OPERATIONS MANAGEMENT

Competency: Operations

Metrics/Cost Models

Facility Operating Gross Square Foot (GSF) Index (SAM Performance Indicator: APPA 2003)

Custodial Costs per square foot

Grounds Keeping Costs per square foot

Energy Costs per square foot

Energy Usage

Utility Costs per square foot

Waste Removal Costs per square foot

Facility Operating Current Replacement Value (CRV) Index (SAM Performance Indicator: APPA 2003)

Energy Usage

This performance indicator is expressed as a ratio of British Thermal Units (BTUs) for each Gross Square Foot (GSF) of facility, group of facilities, site or portfolio. This indicator represents a universal energy consumption metric that is commonly considered a worldwide standard. This energy usage metric can be tracked over a

given period of time to measure changes and variances of energy usage. Major factors that effect BTU per gross square foot are outside ambient temperature, building load changes, and equipment efficiencies. The amount of energy it takes for heating, cooling, lighting and equipment operation per gross square foot. The

indicator is traditionally represented as total energy consumed annually or monthly. All fuels and electricity are converted to their respective heat, or BTU content, for the purpose of totaling all energy consumed.

Energy Usage = British Thermal Units = BTUs

Gross Area = GSF

Facility Operating Current Replacement Value (CRV) Index

This indicator represents the level of funding provided for the stewardship responsibility of an organization’s capital assets. The indicator is expressed as a ratio of annual facility maintenance operating expenditure to current replacement value (CRV). Annual facility maintenance operating expenditures includes all

expenditures to provide service and routine maintenance related to facilities and grounds. It also includes expenditures for major maintenance funded by the annual facilities maintenance operating budget. This category does not include expenditures for major maintenance and/or capital renewal funded by other accounts, nor does it include expenditures for utilities and support services such as mail, telecommunications, public safety, security, motor pool, parking, environmental health and safety, central receiving, etc.

Facility Operating CRV Index = Annual Facility Maintenance Operating Expenditures ($)

Current Replacement Value ($)

Facility Operating Gross Square Foot (GSF) Index

This indicator represents the level of funding provided for the stewardship responsibility of an organization’s capital assets. The indicator is expressed as a ratio of annual facility maintenance operating expenditure to the institutions gross area. Annual facility maintenance operating expenditures includes all expenditures to

provide service and routine maintenance related to facilities and grounds. It also includes expenditures for major maintenance funded by the annual facilities maintenance operating budget. This category does not include expenditures for major maintenance and/or capital renewal funded by other institutional accounts, nor

does it include expenditures for utilities and support services such as mail, telecommunications, public safety, security, motor pool, parking, environmental health and safety, central receiving, etc.

Facility Operating GSF Index = Annual Facility Maintenance Operating Expenditures ($)

Gross Area (GSF)

Operations

All activities associated with the routine, day to day use, support and maintenance of a building or physical asset; inclusive of administration, management fees, normal/routine maintenance, custodial services and cleaning, fire protection services, pest control, snow removal, grounds care, landscaping, environmental

operations and record keeping, trash-recycle removal, security services, service contracts, utility charges (electric, gas/oil, water), insurance (fire, liability, operating equipment) and taxes. It does not include capital improvements. This category may include expenditures for service contracts and other third-party costs.

Operational activities may involve some routine maintenance and minor repair work that are incidental to operations but they do not include any significant amount of maintenance or repair work that would be included

as a separate budget item.

Normal/Routine Maintenance and Minor Repairs

Cyclical, planned work activities funded through the annual budget cycle, done to continue or achieve either the originally anticipated life of a fixed asset (i.e., buildings and fixed equipment), or an established suitable level of performance. Normal/routine maintenance is performed on capital assets such as buildings and fixed equipment to help them reach their originally anticipated life. Deficiency items are low in cost to correct and are normally accomplished as part of the annual operation and maintenance (O&M) funds. Normal/routine maintenance excludes activities that expand the capacity of an asset, or otherwise upgrade the asset to serve

needs greater than, or different from those originally intended.

Predictive Maintenance/Testing/Inspection

Routine maintenance, testing, or inspection performed to anticipate failure using specific methods and equipment, such as vibration analysis, thermographs, x-ray or acoustic systems to aid in determining future maintenance needs. For example, tests to locate thinning piping, fractures or excessive vibration that are indicative of maintenance requirements.

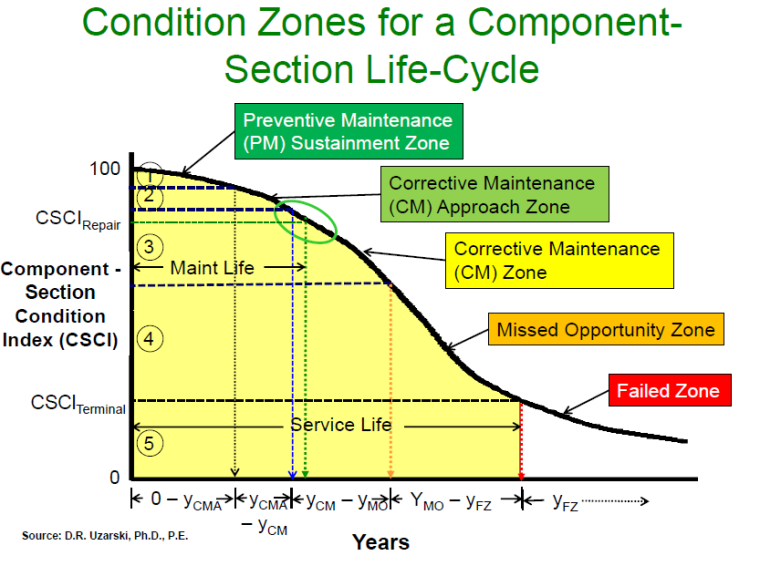

INDUSTRY: OPERATIONS MANAGEMENT

Competency: Planned Maintenance

Metrics/Cost Models

Planned/Preventive Maintenance Costs per square foot

Planned or Programmed Maintenance

Includes those maintenance tasks whose cycle exceeds one year. Examples of planned or programmed maintenance are painting, flood coating of roofs, overlays and seal coating of roads and parking lots, pigging of constricted utility lines and similar functions.

Preventive Maintenance

A planned, controlled program of periodic inspection, adjustment, cleaning, lubrication and/or selective parts replacement of components, and minor repair, as well as performance testing and analysis intended to maximize the reliability, performance, and lifecycle of building systems, equipment, etc. Preventive

maintenance consists of many check point activities on items, that if disabled, may interfere with an essential installation operation, endanger life or property, or involve high cost or long lead time for replacement.

INDUSTRY: OPERATIONS MANAGEMENT

Competency: User Requested Needs

Metrics/Cost Models

Emergency Maintenance Costs as a percentage of Annual Operations Expenditures.

Unscheduled/Unplanned Maintenance Costs as a percentage of Annual Operations Expenditures.

Emergency Maintenance

Unscheduled work that requires immediate action to restore services, to remove problems that could interrupt activities, or to protect life and property.

Unscheduled/Unplanned Maintenance

Reactive and non-emergency corrective work activities that occur in the current budget cycle or annual program. Activities may range from unplanned maintenance of a nuisance nature requiring low levels of skill for correction, to non-emergency tasks involving a moderate to major repair or correction requiring skilled

labor.

INDUSTRY: OPERATIONS MANAGEMENT

Competency: Repairs

Metrics/Cost Models

Repair costs (man hours and materials) as a percentage of Annual Operations Expenditures

Repair(s)

Work that is performed to return equipment to service after a failure, or to make its operation more efficient.

The restoration of a facility or component thereof to such condition that it may be effectively utilized for its designated purposes by overhaul, reprocessing, or replacement of constituent parts or materials that have deteriorated by action of the elements or usage and have not been corrected through maintenance.

Routine Repairs

Actions taken to restore a system or piece of equipment to its original capacity, efficiency or capability.

Routine repairs are not intended to increase significantly the capacity of the item involved. For example, the replacement of a failed boiler with a new unit of similar capacity would be a routine repair project. However, if the capacity of the new unit were double the capacity of the original unit, the cost of the extra capacity would

have to be capitalized and would not be considered routine repair work.

Emergency Repairs

Requests for system or equipment repairs that are unscheduled and unanticipated. Service calls generally are received when a system or component has failed and/or perceived to be working improperly. If the problem has created a hazard or involves an essential service, an emergency response may be necessary.

Conversely, if the problem is not critical, a routine response is adequate.

Unscheduled/Unplanned Maintenance

Requests for system or equipment repairs that – unlike preventive maintenance work – are unscheduled and unanticipated. Service calls generally are received when a system or component has failed and/or perceived to be working improperly. If the problem has created a hazard or involves an essential service, an emergency response may be necessary. Conversely, if the problem is not critical, a routine response is adequate.

Reactive and/or emergency corrective work activities that occur in the current budget cycle or annual program.

Activities may range from unplanned maintenance of a nuisance nature requiring low levels of skill for correction, to non-emergency tasks involving a moderate to major repair or correction requiring skilled labor, to emergency unscheduled work that requires immediate action to restore services, to remove problems that

could interrupt activities, or to protect life and property.

INDUSTRY: CAPITAL ASSET MANAGEMENT

Competency: Retrofits/Upgrades

Metrics / Cost Models

FCI (Facility Condition Index) = DM (Deferred Maintenance) + CR (Capital Renewal)

CRV (Current Replacement Value)

Recapitalization Rate, Reinvestment Rate

Deferred Maintenance Backlog

Facilities Deterioration Rate

Capital Asset Management

The identification and prioritization of facility and infrastructure physical, functional, and budgetary needs, spanning a multi-year timeframe. Also includes the process of reinvesting funds into physical assets in support of the organizational mission, above and beyond normal routine operations and maintenance.

Capital (Major) Maintenance/Repairs

Previous or future repairs or replacement, paid from the capital funds budget and not funded by normal

maintenance resources received in the annual operating budget cycle.

• Repairs – work to restore damaged or worn-out assets/systems/components (e.g., large scale roof

replacement after a wind storm) to normal operating condition.

• Replacement – an exchange of one fixed asset for another (e.g., replacing a transformer that blows up and shuts down numerous buildings) that has the same capacity to perform the same function.

Minimum dollar threshold levels for capital renewal are set by the building owners/manager, however typically

in excess of $5,000 or $10,000.

Deferred Maintenance/Deferred Maintenance Backlog/Accumulated Deferred Maintenance Backlog

The total dollar amount of existing maintenance repairs and required replacements (capital renewal), not accomplished when they should have been, not funded in the current fiscal year or otherwise delayed to the future. Typically identified by a comprehensive facilities condition assessment/audit of buildings, grounds,

fixed equipment and infrastructure. These needs have not been scheduled to be accomplished in the current budget cycle and thereby are postponed until future funding budget cycles. The projects have received a lower priority status than those to be completed in the current budget cycle. For calculation of facility condition index

(FCI) values, deferred maintenance does not include grand fathered items (e.g., ADA), or programmatic requirements (e.g, adaptation).

Deferred Maintenance Backlog Deterioration/Plant (Facilities) Deterioration Rate

Facilities and equipment are in a constant state of degradation. While identified deficiencies/requirements are being corrected, other deficiencies/requirements are continuously being created over time. The rate of deterioration may be expressed as a percentage of current replacement value per year. While degradation

rates vary as a function of multiple variables such as building type, current conditions, geographic location, etc., a benchmark deterioration rate for a reasonably well maintained facility is approximately 2.5% per annum.

Varying annual capital reinvestments into the physical plant and equipment may alter the degradation rate. The facility condition index (FCI) can be used as comparative metric to help monitor degradation rates.

Deficiency/Requirement (Facility/Structure/Asset)

The quantitative difference, typically in terms of dollars amount and associated physical requirements, between an assets current physical or functional condition, and an established minimum level of condition/performance.

Any problem or defect with materials or equipment.

Facility Condition Assessment (FCA)/Audit

The structured development a profile of existing facilities conditions, typically placed in an electronic database format, and populated with detailed facility condition inspection information. A detailed facility condition assessment (FCA’s) typically involve an assessment team of three professionals (architect, mechanical

engineer, electrical engineer), and depend up robust, scalable methodologies to assure accurate and consistent information. It is recommended that FCA’s be done on a regular basis, approximately every three years, or conducting a portion of the overall portfolio annually. The FCA identifies existing deficient conditions

(requirements), in logical grouping and priorities, and also, associated recommended corrections and corrective costs. Costs are generally based upon industry standard cost databases (e.g., Building News, Craftsman Book Company, Richardson General Construction Estimating Standards, RSMeans).

Facility Conditional Assessment Program (Facility Capital Planning and Management Program)

A continuous systematic approach of identifying, assessing, prioritizing, and maintaining the specific maintenance, repair, renewal, and replacement requirements for all facility assets to provide valid documentation, reporting mechanisms, and budgetary information in a detailed database of facility issues.

Facility Condition Index (FCI)

A comparative industry indicator/benchmark used to indicate the relative physical condition of a facility, group of buildings, or entire portfolio “independent” of building type, construction type, location or cost. The facility condition index (FCI) is expressed as a ratio of the cost of remedying existing deficiencies/requirements, and

capital renewal requirements to the current replacement value (i.e., FCI=(DM+CR)/CRV). The FCI provides a

corresponding rule of thumb for the annual reinvestment rate (funding percentage) to prevent further accumulation of deferred maintenance deficiencies. The FCI value is a snapshot in time, calculated on an annual basis. Forecasted FCI values for a building in the future, for example, would include the current deferred maintenance items, plus projected values of capital renewal requirements. The FCI is represented on

a scale of zero to one, or 0% to 100%, with higher FCI values, representing poorer facility’s condition. While property owners/managers establish independent standards, a “fair to good facility” is generally expressed as having an FCI of less than 10-15%.

(FCI) = Deferred Maintenance + Capital Renewal (see definition for Deferred Maintenance)

Current Replacement Value (see definition for Current Replacement Value)

Programmed Major Maintenance: Includes those maintenance tasks whose cycle exceeds one year. Examples of programmed major maintenance are painting, roof maintenance, (flood coating), road and parking

lot maintenance (overlays and seal coating), utility system maintenance (pigging of constricted lines) and similar functions.

Recapitalization/Reinvestment Rate

A facility, system, or component with existing deficiencies will deteriorate at a faster rate than a component that

is in good condition. The level of annual funding for facility renewal and deferred maintenance expressed as a percentage of facility replacement values. Altering the recapitalization/reinvestment rate has direct impact upon the facility condition index (FCI) and associated deferred maintenance levels over time.

Systems Lifecycle Costing

An estimating procedure used to determine the cost of facility system/component renewal based on the average useful life of an individual component. This procedure is typically based upon visual observations, via a facilities conditions assessment/audit, to determine the remaining useful life of a system and the development of cost models for the facility. This process enables multi-year modeling of future replacement

costs and timing.

INDUSTRY: CAPITAL ASSET MANAGEMENT

Competency: Improvements

Metrics / Cost Models

FCI (Facility Condition Index) = DM (Deferred Maintenance) + CR (Capital Renewal)

CRV (Current Replacement Value)

AI (Adaptive Index) or PI (Programmatic Index) = PR (Program Requirements)

CRV (Current Replacement Value)

FQI (Facility Quality Index) or Quality Index or Index = FCI (Facility Condition Index)+ AI (Adaptive Index)

Adaptation/Renovation/Modernization

The improvement, addition or expansion of facilities by work performed to change the interior alignment of space or the physical characteristics of an existing facility so it can be used more effectively, be adapted for new use, or comply with existing codes. Includes the total amount of expenditures required to meet evolving

technological, programmatic or regulatory demands.

Adaptation Index or Adequacy Index (AI)/Programmatic Index (PI)

A comparative inter/intra sector metric/benchmark expressed a value from 0.0 to 1.0 that indicate the program/mission-based condition of a facility. AI is calculated by dividing the total value of deferred physical programmatic/adaptive requirements (PR) by the current replacement value (CRV) (i.e., AI=PR/CRV).

Program-based or programmatic requirements are facilities-specific needs that are established to meet the mission of the facility or organization, inclusive of evolving technological, programmatic or regulatory demands.

Taking an educational science laboratory as an example, while an existing lab may have zero physical deficiencies the configuration and equipment (fume hoods, lighting, computer networks, etc.) may not be suitable for current teaching methods. All of the physical, program-related needs therefore have a cost to remedy and are considered as programmatic deficiencies. Similar to physical deferred maintenance, deferred

programmatic requirements are those current needs that are not funded in the present fiscal year. Additionally, the facilities-specific programmatic requirements may include items such as space, configuration, adjacency,

security, etc.

Improvements

A change or addition to an asset that improves its performance or appearance and/or extends its useful life.

Replacement of Obsolete Items

Refers to work undertaken to bring a component or system into compliance with new codes or safety regulations or to replace an item that is unacceptable, inefficient, or for which spare parts can no longer be obtained.

INDUSTRY: CAPITAL ASSET MANAGEMENT

Competency: Replacements

Metrics / Cost Models

FCI (Facility Condition Index) = DM (Deferred Maintenance) + CR (Capital Renewal)

CRV (Current Replacement Value)

AI (Adaptive Index) or PI (Programmatic Index) = PR (Program Requirements)

CRV (Current Replacement Value)

FQI (Facility Quality Index) or Quality Index or Index = FCI (Facility Condition Index)+ AI (Adaptive Index)

Capital Renewal Index (SAM Performance Indicator: APPA 2003)

Capital Project/Construction

A new facility, rehabilitation/renovation or major maintenance that increases the value of the location/site/campus (e.g., a new building) or extends the useful life of a facility. This work includes construction and purchase of fixed equipment. (e.g., a replacement chiller). Minimum dollar threshold levels for capital projects are set by the building owners/managers, however typically in excess of $5,000 or $10,000.

Capital Renewal (CR)/ Replacement

The systematic management process of planning and budgeting for known future cyclical repair and replacement requirements that extend the life and retain the usable condition of facilities and systems, not normally contained in the annual operating budget. This includes major activities that have a maintenance

cycle in excess of one year (e.g., replace roofs, paint buildings, resurface roads, etc.). The cyclical replacement may be for all or a significant portion (e.g., the replacement of 50% or more of a building system component (lighting system, roof system, etc.) as it reaches the end of its useful life, of major components or infrastructure systems, at or near the end of their useful service life. These activities may extend the useful life

and retain the usable condition of an associated capital asset (e.g., replacement of an HVAC system, extending the usable life of a facility). Replacement may be capitalized based on the Governmental Accounting Standards Board/Financial Accounting Standards Board (GASB/FASB) definition. A depreciation model calculates a sinking fund for this maintenance activity. Costs are estimated by a current replacement

value that is derived by industry standard cost databases, (e.g., Building News, Craftsman Book Company, Richardson General Construction Estimating Standards, RSMeans).

Capital Renewal Index

This indicator shows the relative funding effectiveness in addressing identified capital renewal and renovation/modernization needs. The numerator of this ratio is a total of the annual capital renewal expenditure and the annual renovation/modernization expenditure. Annual Capital Renewal Expenditures are all expenditures over and above facility maintenance operating budget expenditures required to keep the physical plant in reliable operating condition for its present use. These expenditures are over and above normal maintenance for items with a lifecycle in excess of one year and are not normally contained in an annual facility operating budget. This is a separately funded, uniquely identified program that renews, replaces, or renovates building systems on a schedule based on lifecycle recommendations and on assessment of expected remaining useful life. This is typically represented as a total expenditure for capital

renewal of an organization’s capital assets. Plant renewal focuses on maintaining the operability, suitability, and value of capital assets. It is accomplished through the replacement and rework of those components of a building that wear out even though those components are routinely maintained. Capital or plant renewal is a time-driven process with specific useful life cycles for heating and ventilation systems, etc. This is often provided in the form of capital funding for “major maintenance” before it becomes “deferred.”

Capital Renewal Index = Annual Capital Renewal and Renovation/Modernization Expenditure ($)

Current Replacement Value ($)

(SAM Performance Indicator: APPA 2003)

Current Replacement Value (CRV)

The total expenditure in current dollars required to replace any facility at the institution, inclusive of construction costs, design costs, project management costs and project administrative costs. Construction costs are calculated as replacement in function vs. in-kind. The value of design (6%), project management (10-12%),

and administrative costs (4%) can be estimated at 20% of the construction cost. The value of property/land however is excluded, and insurance replacement values or book values should not be used to define the current replacement value. Costs for the replacement value are typically generated using a cost models based upon the use of reference cost databases using the building construction type, user and use categories, quality level, buildings systems and or subsystems/components/units, and local experience. The property owner/manager may decide, for internal purposes, to base the current replacement value (CRV) on “replacement in kind” (duplicate constructions techniques), vs. “replacement in function” (e.g., six story office

space). The CRV’s for associated infrastructure, such as utility systems, and generating plants, roadways, non-building structures (e.g., dam, bridges, etc.) are developed in a similar manner.