JOB ORDER CONTRACTING

Job Order Contracting GUIDELINES & PROCEDURES

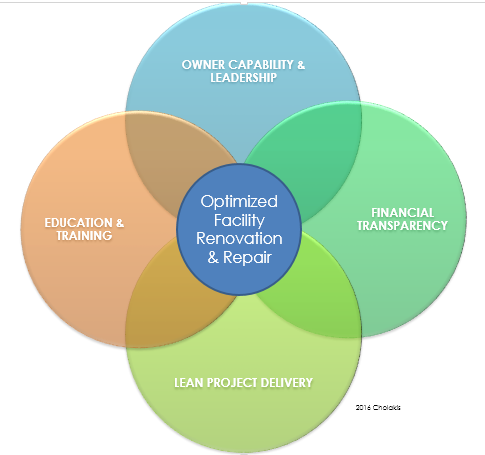

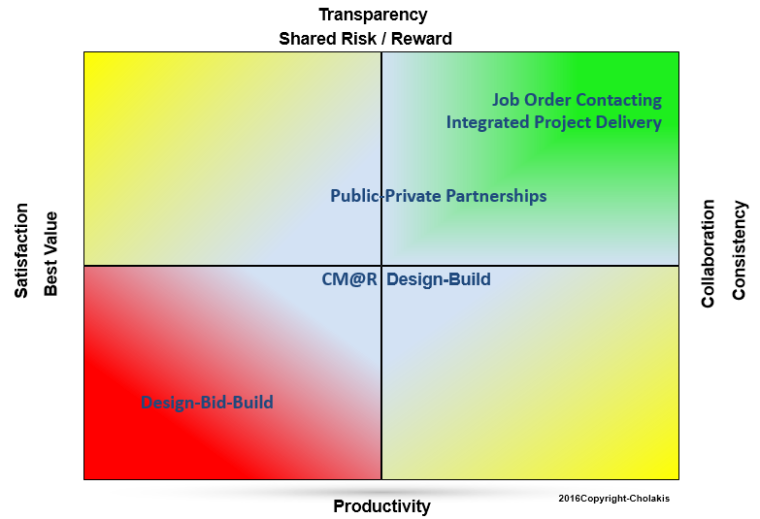

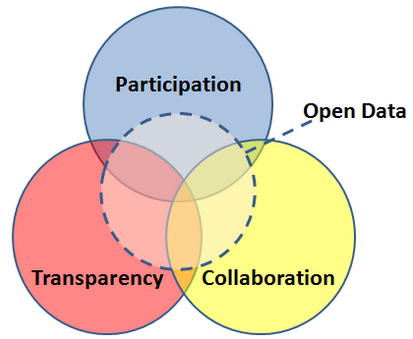

LEAN best management practices are integral to the administration of a Job Order Contract (JOC). Job order contracts, provides a flexible and responsive contractual capability in supporting its real property maintenance and renovation mission.

Job Order Contracting enables a pre-qualified contractor(s) to perform repair, renovation, or minor construction of a facility or other form of built structure based on pre-described and pre-priced tasks as defined within a Unit Price Book – UPB.

The procurement process for a JOC contractor begins with an Owner request for proposal (RFP) where the real property Owner identifies the type(s) of work for which it is requesting services. The contractor(s) may submit sample bids and a coefficients (a multiplier(s) to be applied to the referenced unit price book.

The intent and purpose of the Request for Proposal (RFP) is to establish a term contract to provide on demand, quality general construction services (renovation, repair, sustainability, minor new construction ) for the Owner.

JOC, an annual contract and multiple option year agreement for general construction, generally requires the Contractor to e furnish associated labor, tools, materials, equipment and transportation. The Owner provides an overall JOC manager, generally a procurement/purchasing authority, and a Project Manager / Coordinator assigned to each project during all phases of a project, including construction.

Projects may be architectural (finishes) , electrical, mechanical and/or plumbing in nature. Asbestos and similar abatement may also be included if part of an overall project. The architectural scope includes, but is not limited to, demolition and construction of building exteriors and interiors and may include suspended ceilings, gypsum and masonry walls, metal frames and solid core doors, and resilient flooring. The electrical may consist of, but not be limited to, demolition and construction of building electrical systems and may include service and distribution, general lighting, communications, controls and instrumentation, and other systems. The mechanical may consist of, but not be limited to, demolition and construction of building mechanical systems, and may include rough and finish plumbing in cold and hot water, chilled water, and steam drain piping, the construction and extension of ducts in supply, return and heating ventilation and air conditioning systems (HVAC), the installation of fan coil units or DX type air conditioning systems, and hot water and steam generators.

A JOC generally includes a nominal guaranteed minimum contract value for the initial year, and for exercised option period during the term of a multi-year program, provided the Owner has been reasonably satisfied with the contractor’s performance to date.

Notwithstanding the foregoing, an Owner is not obligated to issue task orders or an amount of work beyond the stated minimum.

Work Limits

The JOC established a dollar limit per task order, for example $100,000 or $150,000 per job order. It is generally not acceptable to split a project into more than one JOC in order to stay under the maximum amount.

Term

Contractors are generally selected as part of a multi-year agreement, and/or for one year with tw0(2) to four(4) option years.

Unit Price Books

The “Facilities Construction Cost Data” historically provided by the RSMeans Company, LLC and similar line item cost books are used for the vast majority of job order contracts. Generally the most recent edition of the UPB is used for Year 1 of the JOC, and updated annual. Quarterly economic factors are also viewed as a best practice.

If the does not provide appropriate pricing for required tasks and/or the best value for the Owner, the Contractor should be allowed to provide alternative pricing for consideration during the proposal process and show a cost comparison (cost/benefit) option to the Owner for consideration. It is expected that the chosen contractors will always provide the best value option for the Owner on all projects for which they are contracted.

Specifications

Best practice Job Order Contracts typically rely upon the Owner’s existing construction design specifications, and the UPB. Individual task orders generally include drawings, detailed unit prices, and reference specifications.

The Technical team (Facilities Management / Engineering) develops specifications and plans necessary for the procurement and implementation of the JOC. The intent of the specifications is to furnish concise organizational standards for maintenance, repair, and construction of Owner facilities.

Where the unit price offers minimum/maximum costs associated with a particular task, or if the task is not listed in the unit price book, the Contractor will submit a not-to-exceed time and materials proposal for the specific task to the Owner for approval.

Job Orders / Task Orders

A job order (JO) or task order (TO) is the contractual document issued by the purchasing/procurement or its designated representative to the Contractor. The Contractor provides a detailed line estimate as the TO proposal, submitted to the Owner for review and approval, itemizing tasks and quantities of labor, materials, and equipment to do the work. The TO is issued and approved upon agreement between the Owner (purchasing/contracting and engineering/technical/facility management) and the Contractor on the scope of work, performance time, and the price for that work.

The Notice to Proceed (NTP) is provided by the Owner (procurement/contracting/purchasing) and issued to the Contractor.

Non-Pre-Priced Work

Non-pre-priced works includes tasks that are not specifically included in the unit price, but are within the basic intent and general scope of the JOC, and/or tasks which are included in the unit price, but require adjustment because of unusual site conditions which differ materially from those ordinarily encountered and generally inherent in the character of the

If materials specified by the Owner Technical team for a specific task exceeds the unit material bare cost in the unit price book, the Contractor may be allowed increase and adjust the bare cost as needed. In these instances, copies of at least two (2) competitive materials vendor quotations should be submitted to the Owner to substantiate material costs in excess of the unit

If the JO task is not defined in the unit price book, material costs should be reimbursed to the Contractor, based on the actual cost of materials to the Contractor from its usual sources of supply with all usual trade practice discounts deducted. All cash discounts should be deducted in determining material costs.

The Contractor provides equipment and material as specified by the Owner from sources at the least cost to the Owner. Competitive quotations shall be secured wherever feasible, and in all instances, when requested by the Owner. Contractor will be required to provide copies of invoices and proof of payment when requested by the Owner. Contractor is responsible for receiving and securing materials, including unloading of delivery trucks, checking deliveries, and transportation to the work area. Owner staff are not responsible for this.

The Owner reserves the right to purchase material or job-required merchandise. Materials not used on the job shall be returned to the Owner’s stock for credit to job. The Owner will be required to deliver such materials to the job site or compensate the Contractor for providing labor to deliver Owner-furnished materials to the job

Equipment

Equipment costs can be included in the task order only if a unit cost for equipment is listed for the specific task in the unit price book, and actually on the job. The Contractor shall furnish as part of its overhead cost, included in the coefficient, all necessary protective equipment, concrete mixing boxes, water barrels, wheelbarrows, hoes, shovels, tools, mortar boards, ladders, portable scaffolding, shop tools, hand tools, shop equipment, and fabricating items customary to the trade, etc., and all other movable equipment necessary to complete the work performed under this contract. The furnishing of tools shall include all maintenance, fuel, loss and breakage. Any equipment reimbursements must be approved by the Owner prior to its use.

Labor

Labor costs will be reimbursed to the Contractor at the unit price rate multiplied by the Contractor negotiated coefficient(s). The Owner will not recognize any premium or incentive pay and no work shall be performed on an overtime basis or shift differential and no overtime pay or shift differential shall be included as a “job cost” unless the performance of such overtime or shift differential has been authorized by the issuance of an additional letter of acknowledgement on a particular project or as agreed to in the submitted TO by the Contractor, or as required in the scope of work issued by the Owner, and/or a separate coefficient is allowed.

If a task is not properly identified in the unit price book, then the Contractor will be reimbursed for only laborers and journeymen at their respective hourly labor rates (inclusive of salary only), multiplied by the negotiated coefficient. Taxes, insurance, fringe benefits, and vacation allowances are to be included in the Contractor’s coefficient.

As per the Owner’s General Conditions, a worker with overall project supervisory authority is to be present on the job site at all time. Supervisory costs are to be part of Contractor’s negotiated coefficient and will not be reimbursed as a separate labor.

Travel time or costs associated with transportation between an employee’s residence and job site are not reimbursable. Out of state travel of any kind will not be reimbursed or allowed in the cost model.

The Contractor shall perform the work under this Contract on the job site in association with Owner staff, other Owner Contractors, and/or Subcontractors, per JOC stimulations (whether union / Davis-Bacon, or non-union and shall complete the work assigned in the time required.)

If off-site time and materials work is required, such as site fabrication, the Owner shall be so notified at the time of the issuance of the TO by the Contractor. The Owner reserves the right to inspect such off- site work at any

The Contractor shall maintain a local office with telephone available for receiving and making calls throughout the working day and shall have available sufficient storage space for materials and equipment if its local office is not located within 50 miles of the work site.

The response time of the Contractor (or Contractor’s representative with equal authority) to the Owner is stipulated in the contract, i.e. Monday through Friday, 8:00 AM to 5:00 PM and/or normal working hours.

Subcontracts

When it is necessary for the Contractor may be allowed to use the services of a Subcontractor. The Contractor may be reimbursed for Subcontractor at cost plus the negotiated coefficient. Proposals to the Contractor under both the unit price and time and material methods and consist of a “Not to Exceed” time and material nature. Copies of the subcontractor proposals are to be a part of the Task Order submittal, and shall be included as backup. At the completion of the project, any savings associated with the Subcontract may be required to be passed along to the Order by way of a change order.

The Contractor shall, as soon as practicable, and before the execution of the contract, notify the Owner in writing of the names of Subcontractors proposed for the principal parts of the work and that of other Subcontractors, as the Owner may direct. The Contractor shall not employ any Subcontractors that the Owner may object to as being incompetent, unfit, irresponsible or

The Contractor agrees that it is fully responsible to the Owner for the acts and omissions of the Subcontractor(s) and any person(s) directly employed by them (Subcontractor), as he/she is for the acts and omissions of persons directly employed by them (Contractor).

Nothing contained in the JOC or contract documents shall create any contractual relation and/or obligation between any Subcontractor and the Owner, and nothing in the contract documents is intended to make the subcontractor a beneficiary of the contract between the Owner and the Contractor.

The Contractor agrees to bind every Subcontractor, and will see that every Subcontractor agrees to be bound by the terms of the JOC and related contract documents, and each of these as far as is applicable to their work, unless specifically noted to the contrary in a subcontract, approved in writing, as adequate by the Owner.

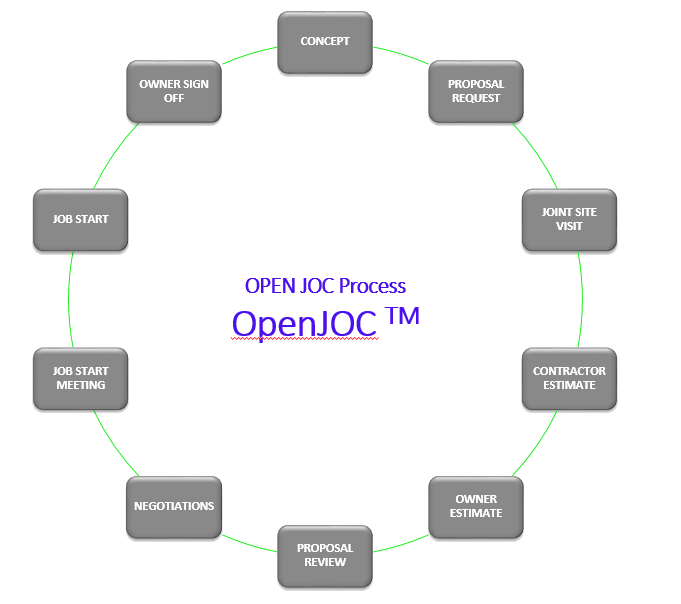

Execution Procedures

Owner Technical Team – Facilities Management / Engineering – Work Coordination

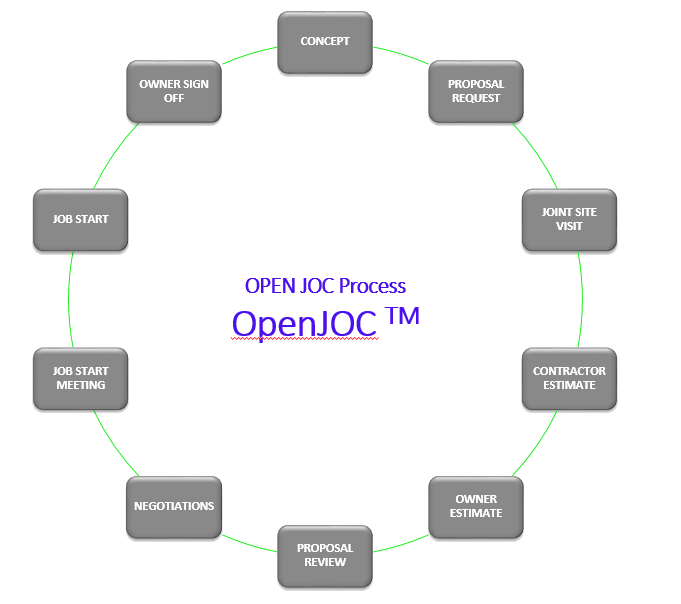

Owner submits request for maintenance, construction, or facility modification by completing an established form and submitting it through the JOC established authority (generally Purchasing/Procurement/Contracting).

The JOC authority and the Owner Technical Team will then perform the following actions once the form is received:

- Request is assessed for validity and

- Priority is established, a gross scope and cost estimate range is associated

- The funding source is identified and funds available for the requested work are

- Preliminary plans and specifications are generated

- Plans and specifications are noted

Initial Review of Proposed Project with Contractor

Facilities Management / Engineering contacts the Contractor. The primary Contractor or primary Contractor’s representative shall respond within an established time frame (i.e. two (2) calendar days) by meeting with the Owner Technical Team (and possibly the end-user customer) to conduct a scope validation site visit and conference. During this meeting, the following issues will be discussed and established:

- Project number and title

- Site investigation

- Methods and alternatives for accomplishing work

- Definition and refinement of requirements

- Detailed scope of work

If the primary Contractor is unable to respond to the initial contact by Owner within the given amount of time, the Owner reserves the right to contact an alternate contractor for a proposal on the project.

Owner Facilities Management/Engineering and Contractor JOC Activities

Owner formally requests the Contractor to make a proposal by listing the project title and Task Order/Job Order number, acknowledging the scope of work, and any special instructions or conditions that may exist, as per plans.

The Contractor is responsible for preparing a detailed proposal by identifying tasks, refining quantities, pricing priced an d non-pre-priced tasks, developing performance times and preparing a proposal document. The Contractor furnishes this proposal to the Owner within and established timeframe (i.e. within five (5) calendar days from the date of the initial site visit).

Owner reviews the Contractor’s proposal for completeness, tasks and pricing data. Owner reviews the Contractor’s proposed performance time. The reasonableness of the Contractor’s price proposal is authenticated by comparing it with Owner estimate or a review of the Contractor’s line item estimate by the Owner.

After a review of the proposal, the Owner will either approve the proposal or will set up and conduct a proposal review meeting with the Contractor and negotiate any variations involving price, time, and quantities.

If Contractor’s proposal is not acceptable, the proposal may be returned to the Contractor for additional development, or; the Owner determines the project should be canceled, delayed, accomplished by other means, or reassessed.

Upon validation that the project should be accomplished, the project package will be compiled by Owner and a Job Order / Task Order issued to the Contractor.

The project package is to include:

Any Owner work request, correspondence, including estimates, plans and specs, General and Supplementary Conditions including funding, Contractor proposal, Record of negotiations, Owner Task Order/Job Order, etc. and any other required various forms completed by the Contractor.

Once the Task Order/Job Order is approved and issued, the Contractor will begin work as per date ranges. The Owner will perform the contract administration associated with the until work completion, including the final inspection and acceptance. Upon acceptance and certification of work completion by the Owner, all required delivery order data will be filed in the JOC electronic record system and other required areas.

At the time of project completion, the Contractor will submit a Certificate for Payment or similar document to be approved by the Owner JOC authority. The Owner may hold a retainage for completion of any punch list(s) for the estimated cost to complete the punch list and /or release of liens.

Modification to Job Orders

If differing site conditions are encountered during execution of the Task Order/Job Order, or there is a desired change to quantity or quality of work, then the Task Order/Job Order must be amended.

Generally,issuing modifications may be required due to differing site condition (unforeseen conditions), increased scope of work (requested/approved by the Owner), decreased scope of work (requested/approved by Owner), and/or time / schedule adjustments.

All modifications must include a detailed explanation of the circumstances that caused the modification.

Reporting Requirements and Payments

All work flows, reporting requirements, and payment procedures are specified in the Job Order Contract. The will be responsible for administering all task orders under the Job Order Contract with Finance/Purchasing/Contracting, Internal Audit, Contracts Administration, and the Technical Team providing guidance.

Application and Certification of Payment shall be submitted by the Contractor using properly executed forms provided by the Owner, including any set-aside documentation.

Upon receipt of Contractor invoices and approval of work thus far completed, the Owner makes payment to Contractor for work completed and materials purchased for the Task Order.

Final payment shall be made to the Contractor promptly after final completion of work and acceptance by the Owner as stipulated per the Job Order Contract.

The Owner generally reserves the right to deduct from the contract sum an equitable amount for any damaged or uncorrected work until such time as the work is deemed to be satisfactory by the Owner.

The Owner may withhold or, on account of subsequently discovered evidence, nullify the whole or part of any payment certificate to such extent as may be necessary to protect the Owner from loss on account of legal claims filed against the Contractor or reasonable evidence indicating probable filing of claims; failure of the Contractor to make payments properly to the Subcontractor or supplier for material or labor; or a reasonable doubt that the work can be completed for any associate unpaid balance.

Exclusive of any issues, payment shall be made with each Application for Payment.

The Owner is responsible for maintaining Job Order Contract information, such as the following:

List of job orders, with description and dollar amount, issued.

List of job orders, with description and dollar amount, completed.

Status of all incomplete job orders

Statement of total number and dollar amount of job orders issued for each.

List of job order modifications issued during the

Owner Proposal Rejection Right

The Owner reserves the right to reject any proposal if the evidence submitted by a proposer, or if an investigation of such proposer fails to satisfactorily convince the Owner that such proposer is properly qualified by experience and/or capabilities to carry out the obligations of the contract and satisfactorily complete the work contemplated, or the proposal(s) are deemed not to be in the best interest of the Owner.

JOC Proposal Form

Proposals shall be submitted by the Contractor using the forms furnished by the Owner. Generally the required format is electronic, standardized, and completed using the same/similar software utilized by the Owner. Generally any alternative format will not be accepted by the Owner.

Delivery of Proposals

Proposals are submitted as noted in the Job Order Contract. Typically, this is by done via email, or within some form of online/collaborative software program. A proposals must be submitted at the specified location, and by the specified time set for the “opening” of proposals in order to be accepted by the Owner. Generally the FAX transmissions or paper submissions via mail or hand deliver are not allowed or encouraged.

Terms as Used in All Documents

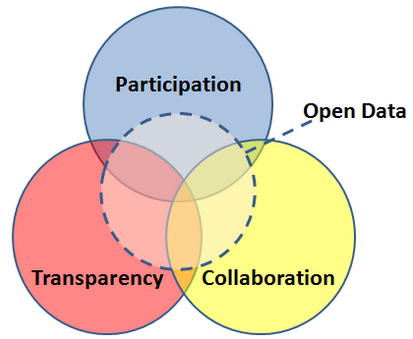

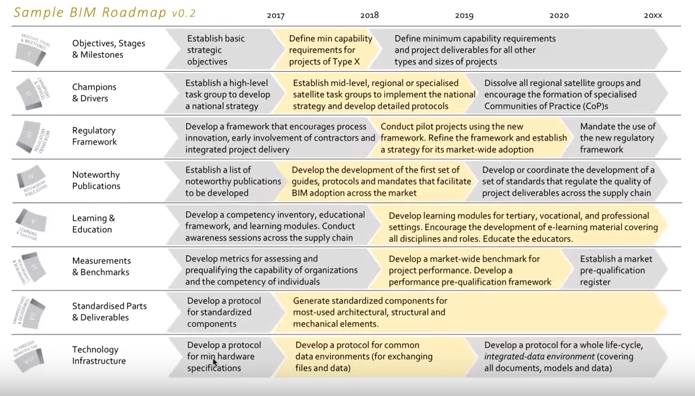

It is critical that standardized terms, definitions, and data architectures be used throughout the Job Order Contract life-cycle, from initial conceptualization through close-out and warranty period.

Owner – Refers the Owner and or Owner authorized representative responsible for the JOC.

Coefficient – A numerical factor which represents costs not considered as included in Unit Price Guide unit prices (examples may or may not included the following as defined in the Job Order Contract document)- general conditions, administrative and other overhead costs, insurance costs, protective gear and clothing, contingencies such as changes in wage rates and inflation, contractor’s profit. Typically JOC coefficients range from 0.80 to 1.20, however, due to unusual site conditions or other requirements, the accepted coefficient my vary beyond this upper or lower limit.

Non Pre-priced Item (NPP) – A necessary unit line item(s) associated part of a JOC Task Order / project that is not within the JOC Unit Price Guide. Generally a coefficient is not applied to a NPP. A limit upon the total value of non pre-priced items associated with a Task Order is generally specified in the Job Order Contract. This value is generally expressed as not to exceed ten percent (10%) of the value an individual task order.

Statement of Work – (SOW) – A description of a task order / project to be ordered under a Job Order which contains sufficient detail to determine quantities, quality, and the time required for completion.

Unit Price Guide – A compilation of real property repair, rehabilitation, alteration, maintenance, and minor construction tasks, along with associated units of measure and unit prices designated or provided by the Owner to be used in administration of this contract. Information is in the form of unit prices times including a description of the task, direct material, labor and equipment costs, but not indirect costs or profit. The Unit Price Guide generally includes approximately 30,000 line items for routine facility management tasks. The number can be far lower in the case of certain “trade” JOCs, such as painting, fencing etc.. The number of line items may also be significantly higher for diverse portfolios and/or requirements. The later two instances represent outliers.

Performance and Payment Bonds

The awarded Contractor generally is required to execute and supply to the Owner with a Payment Bond associated with the JOC, and specified total project/task order values. The accumulative total of the Job Order Contract may be a consideration for establishing bond premiums. Payment Bonds are for the protection of all claimants supplying labor and materials as defined by the scope noted in the fully executed job order/task order.

Performance bonds shall be solely for the protection of Owner / Owner authority awarding the contract.

Time Period

The Owner will assure the facility/area associate with the specified job order/task order will be available. Work must be completed within the specified time frame mutually agreed by the Owner and Contractor. Credit may or may not be given for days of inclement weather based on specifications.

Failure to Complete Work on Time

The time set forth in the job order /task order for the completion of work is an essential element of a Job Order Contract. Contractor’s failure to complete the work within such time will cause damage and/or operational inconvenience(s) to the Owner.

A breach of contract as to completion time will cause damage and liquidated damaged my by associated with the Job Order Contract. For example, for each and every calendar day after the expiration time of the anticipated completion date of the task order/ job order that any work is not completed and accepted, including the correction of deficiencies found during the final inspection, the amount per day, as stipulated, an amount may be deducted from the money due, or to become due to the Contractor, not as a penalty but as compensation to the Owner for additional expenses incurred, and inconvenience caused by failure of the contractor to allow the Owner to receive the premises at the designated time of completion.

Liquidated damages may be assessed for each calendar day for job order contracts. An example is shown in the below table.

| Job Order Amount From To |

Liquidated Damage Per Calendar Day |

| $ —– |

$25,000 |

$42.00 |

| 25,001 |

50,000 |

70.00 |

| 50,001 |

100,000 |

105.00 |

| 100,001 |

500,000 |

140.00 |

| 500,001 |

1,000,000 |

210.00 |

| 1,000,001 |

2,000,000 |

280.00 |

| 2,000,001 |

5,000,000 |

420.00 |

| 5,000,001 |

Over 5,000,000 |

600.00 |

Insurance

The Contractor shall procure and keep in force insurance with companies acceptable to the Owner conforming to a defined schedule. The Contractor shall supply all required insurance prior to starting the project on the scheduled date. The Contractor shall also provide a certificate from the insurance carrier naming the Owner as an additional insured and that the insurance shall not be cancelled until ten (10) calendar days written notice of said impending cancellation has been given to the Owner.

Material

Only new, unused, and first-quality materials or equipment shall be supplied as specified in the Job Order Contract. It is not the intent of the specifications to limit materials, or the products of any particular manufacturer. Where specific materials, equipment and/or fixtures have been specified by name, manufacturer, or catalog number, it has been done to set a specific minimum standard and reference for comparison as to quality, longevity, and performance. There is no intent to discriminate against, or prevent any dealer or manufacturer from furnishing materials, equipment, and/or fixtures which meet or exceed the characteristics of the specified items. However, substitution of materials shall not be made without prior written approval from the Owner.

Contract Warranty and Guarantee

The Contractor warrants all Work against defects in materials, equipment, or workmanship for a period defined in the Job Order Contract. The time period begins upon substantial completion of the entire project, or designated portions of completion.

Correction of Defects – Upon receipt of written notice from the Owner of the discovery of any defects, the Contractor shall remedy the defects and replace any property damaged there from occurring within the warranty and guarantee period. If the Contractor, after notice, fails to proceed promptly and remedy the problem within a defined period (i.e. thirty (30) days or within another period of time which has been agreed to in writing, in compliance with the terms of the warranty and guarantee) the Owner may have the defects corrected and the Contractor and its surety shall be liable for all expenses

State Sales Tax

The Owner may qualify for exemption from State and Local Sales Tax.

Subcontractors

The Contractor shall not assign, sell, transfer, or otherwise dispose of the contract, or any portion thereof, or his/her rights, title and interest therein without the written approval of the Owner, as stipulated in the Job Order Contract. To sublet, assign or otherwise dispose of any portion of the contract shall not relieve the Contractor of any responsibility for the fulfillment of the contract. If the aids of subcontractors are used to complete the project, the contractor will be responsible for supplying the following information about the subcontractors at or before completion of the project:

- Subcontractor name and

- Vendor identification number (if available).

- Set-aside / Small Business Classification (if appropriate).

- Subcontract bid

- Lien

An Identification (I.D.) Badge is required for all contractors, subcontractors and their agents working on or about the Owner property. This is generally a Photo I.D. Badge for any person(s) on site. A Non-Photo, Color-Coded Badge generally required for individuals on site for less a specified period of time to include but not limited to, equipment setup, delivery person(s), and temporary labor crew(s).The Contractor is responsible assure Badges are properly assigned and maintain accurate records and updated lists making information available for inspection upon the Owner’s request.The Badges will be worn and displayed prominently by each cardholder near the front shoulder area.

Site Supervision

The Contractor shall supervise and direct all work using his/her best skills and materials, shall be solely responsible for all construction means, methods, techniques, sequences, and procedures, and for coordinating all portions of work under any contract.

Site Inspection

The Contractor is responsible for having visited the site and having ascertained pertinent local conditions such as locations, accessibility, and general character of the site of buildings, the character and extent of existing scope of work within, and adjacent to the site, and any other work being performed thereon at the time of the submission of their Job Order price.

Trash and Cleanup

The Contractor shall at all times keep the premises free from accumulation of waste materials or rubbish caused by their employees or the work. Upon completion of the project, and prior to the final inspection, the contractor shall have the premises in a neat and clean condition. The Contractor is not to use Owner trash containers for any reason.

Building Codes

Code compliance is mandatory. Contractor is to furnish all materials and equipment and do whatever is necessary to comply with federal, state, and local laws, building codes and environmental regulations.

Safety Precautions and Programs

The Contractor shall be responsible for initiating, maintaining and supervising safety precautions, programs and environmental regulations in connection with the work. For example: Public Law 91-596, 29 U.S.C. Sec.’s 651 et seq., The Occupational Safety and Health Act (OSHA) of 1970, and all amendments thereto, and will enforce and comply with all of the provisions of this act. In addition, on projects in which trench excavation will exceed a depth of five feet (5’-0”); the Contractor and all of its subcontractors shall comply with all requirements of 29 C.F.R. Secs. 1926.652 and 1926.653, OSHA Safety and Health Standards, which are more fully described in the Special Conditions, of the above standard, and shall require a pay item classification, pursuant to Paragraph 7.1, for the particular safety system to be utilized by the Contractor.

Non-Discrimination

The Contractor shall not discriminate against any person because of race, sex, age, creed, color, disability, religion or national origin.

Royalties, Patents and Licenses

It shall be the duty and responsibility of the Contractor and all of its subcontractors to be familiar and comply with all requirements of public law 102-560 enacted by Congress and effective November 28, 1992. The Contractor shall pay all royalties and license fees, and defend all suits or claims for infringement of any patient rights and shall hold the Owner harmless from loss or account thereof, except that the Owner shall be responsible for all such royalties and license fees and loss when a particular design, or process, or the product of a particular manufacturer, or manufacturers is specified; provided, however, if that Contractor has reason to believe the design, process or product specified constitutes an infringement of a patent, he shall be responsible for such royalties, license fees and loss unless he promptly gives such information to the Owner and the Architect and/or Engineer. It will also be required for each contractor to submit with their bid proposal a list of all licenses, or fees they have determined necessary for completion of the contract.

Firearms

All Contractors are advised to inform all their employees the fact that weapons, of any kind, are strictly prohibited. Violators can and will be prosecuted to the full extent of the law by the proper designated authorities.

Wage Scale(s):

The Contractor is generally required to pay not less than the wage scale of the various classes of labor as shown on the “Prevailing Wage Schedule” and/or Davis-Bacon. The specified wage rates are minimum rates only, and the Owner will not consider any claims for additional compensation made by any contract because of payment by the Contractor of any wage rates in excess of the applicable minimum rate contained in the contract. Site work, paving and utility construction crafts may be used only for construction outside of the building line.

Prevailing Wage Rates

The Contractor is required to pay not less than the defined wage scale of the various classes of labors. The specified wage rates are minimum rates only, and the Owner will not consider any claims for additional compensation made by any contract because of payment by the Contractor of any wage rates in excess of the applicable minimum rate contained in the contract. Site work, paving and utility construction crafts may be used only for construction outside of the building line.

Sample Forms

SUBCONTRACTOR INFORMATION

Project Name:

Company:

Signature:

Purchase Order No. Date:

Were Subcontractor(s) Used for this Project? [ ] Yes [ ] No If YES, complete the following information:

Company Name:

Company ID#: *Classification:

Subcontractor Price (HUB’s only) Percentage: _

Company Name:

Company ID#: *Classification:

Subcontractor Price (HUB’s only) Percentage:

Company Name:

Company ID#: *Classification:

Subcontractor Price (HUB’s only) Percentage:

Company Name:

Company ID#: *Classification:

Subcontractor Price (HUB’s Only) Percentage:

*Classification Codes:

NAH = Not a HUB Contractor / HUB = HUB-Minority Owned Contractor / HUB-WO = Woman Owned Contractor

HAZARDOUS CHEMICALS LIST

Project: Located on ___________________________

[ ] No hazardous chemicals will be used on the project.

If, at a later date, it is determined hazardous chemicals will be required, this form must be immediately completed and posted.

The following is a list of hazardous chemicals currently being used or will be used on this project. Further information can be obtained from the material safety data sheets (MSDS). The MSDS pertaining to this work-site will be kept on file at

.

MSDS index # hazardous material

(Name of Material, etc.)

-

-

-

-

-

-

-

-

-

-

Company:

Superintendent’s Signature:

Date: To:

Attention of: Re:

Project Name: Project #:

JOB ORDER CONTRACT REQUEST FOR QUOTE/Proposal

Request for Job Order Contract Price Quote

The Owner hereby requests a written job order price quote to perform the services for the project described herein. The project is located at 4XXXXXXXX. Work to be performed is included in the drawings and project manual titled xxxxxx, FM #xxxxxx, dated xxxxx.

Owner Technical Team (Facilities Management / Facilities Planning and Construction/ Engineering) is the department that will manage this project. A pre-bid conference will be scheduled for the week of xxxxxx. Please submit your proposal and construction schedule to the undersigned Project Manager no later than xxxxxx.

Sincerely,

Xxxxxxxxxxxx

Project Manager, Owner

Attachments: Project Drawings Project Manual

cc: Project File

Job Order Contractor Services Request

Memorandum

Phone:

TO: (Authorizing Manager) Fax:

FROM: (Owner Project Manager) (FM / Engineering Dept.)

DATE:

SUBJECT: Job Order Contractor Services Request Project Number: XXXXXX

Project Name:

The above referenced project requires the procurement of Job Order Contracting Services (JOC). Direct costs for the project are expected to be less than $XX<XXXXX and the project is suitable for the JOC Program. Details in support of this request and justification are as follows:

Name of Requested Contractor: Selection Considerations and Justification

(Check all that apply and explain)

- The requested Contractor offers a scheduling advantage over other available Contractors, (i.e. manpower or workload).

Briefly explain.

- The requested Contractor has demonstrated exceptional performance accomplishing similar projects for Owner which is documented as follows:

FM Project No. FM Project Name Owner 1.

2.

3.

- The requested Contractor possesses an experience advantage over other available Contractors because of its prior construction experience associated with the project area (i.e. knowledge of existing site conditions)

Briefly explain.

- The requested Contractor and one or more other Contractors are equally capable of performing the project, but the requested Contractor has been awarded a lower total dollar amount than other

Briefly explain.

Job Order Contractor Services Request Project Number:

Project Name:

SUBMITTED

By: Date:

(Owner Project Manager)

AUTHORIZED

By: Date:

(Owner Authorizing Manager)

PROJECT MANAGER –

- ATTACH ORIGINAL SIGNED JOC SERVICES REQUEST TO THE VENDOR PURCHASE REQUISITION.

- PLACE DUPLICATE COPY IN THE OFFICE CENTRAL

- PLACE DUPLICATE COPY IN THE PROJECT

HOW TO REVIEW A JOC PROPOSAL – WHAT TO LOOK FOR:

1. Verify the proper coefficient is used and applied

- The negotiated coefficient is applied to the Unit Price Guide line items only, including overtime calculations.

2. Perform a math check on the Proposal Summary

- Math should be checked in the “down column” and it is recommended to check certain high quantity line items “across” the detail

3. Review and check all overtime applications

- This includes crew rates used and the specific application of what is being performed

- The overtime coefficient is the same as the normal working time

- Distinguish between overtime for off-hours labor vs. straight-time with a shift

4. Check and review the line item detail

- Line items should clearly correspond to the scope of work and be categorized by the Construction Specifications Institute

- The formulas cannot be changed or modified in the Unit Price Guide line

5. Review and confirm quantities

- Check the large quantities and the frequency of smaller quantities

- Look for duplication

- Confirm that inter-related line items have appropriate inter-relating quantities, e.g., conduit quantity vs. wire hangers

6. Review and confirm qualifications / clarifications

- Clarifications are important because they confirm or spell out

- Verify how clarifications affect the pricing in the proposal or the scope of

7. Confirm the Job Order duration / final completion

- All projects require a schedule. It should be noted that the final approved schedule can be furnished at an agreed upon later date and may or may not be attached as part of the initial

8. Review the non pre-priced items – NPP

- The goal is to keep non pre-priced items to 10% or less of the direct cost. However, at Owner may have proprietary systems and vendors. Some proposals may exceed the 10% due to the application of these proprietary sources. Authorizing Manager shall approve when non-pre-priced exceeds 10%.

- All non pre-priced line items must have a complete material and labor breakdown

- Confirm that the non pre-priced items are not in the UPB.

9. Review and confirm the bonds

- Applicable performance and payment bond premiums should be added to the sum of the pre-priced and non pre-priced line

- Refer to the 2005 Uniform and Supplementary General Conditions for bonds and insurance

10. Verify the Set-Aside

- Demonstrate participation and/or a good faith

11. Show Your Work!

- Include red lines, comments / notes, printed addition tapes, notes, and confirmations directly on the proposal to substantiate your review. This action is very important as it clearly demonstrates “due diligence” in assuring Owner is getting best (See JOC Proposal format example.)

THE DO’S AND DON’TS OF A JOB ORDER CONTRACTING PROGRAM

DO:

- Know the JOC Contract and its dollar

- Know your contract plans and

- Check the math and extensions of each

- Randomly verify line items and

- Keep non pre-priced scope to less than or equal to 10% of the project direct cost

- Review overtime applications /crew

- Apply the negotiated coefficient to only the unit

- Apply bond costs to the summation of all

- Verify the current approved Unit Price Guide is being used in the

- Question and validate the contractor’s proposal

DON’T:

- Bid any of the approved JOC Contractors against each other and “Shop” bid

- Use only non pre-priced quotes and call it a JOC

- Solicit JOC proposals from non-approved JOC contractors

- Assume a non pre-priced item is not in the Unit Price

- Allow manipulation of the Unit Price Guide units, formulas, or

- Allow non-normal working hour rates (overtime) on tasks that can be completed during normal working hours.

- Apply any City Index adjustments to the estimate unless authorized in the Job Order Contract

- Allow proposals developed other that using Unit Price Guide and noted NPP items.