A Comparison of Construction Cost Estimating Tools

- Spreadsheets – Microsoft Excel®

- Electronic Cost Books and Calculators – RSMeans CostWorks RSMeans Online

- Cost Estimating/Project Management Software – 4Clicks Project Estimator

- Cloud Cost Estimating – Ceasel

Accurate, timely, and transparent cost estimating is critical to the success of any renovation, repair, sustainability, or new construction project. While most construction cost estimators continue to rely primarily upon hardcopy documents and electronic spreadsheets, such as Microsoft Excel, many are beginning to leverage electronic cost books and associated calculator software tools. Both of these approaches have merit and are well suited for certain types of users.

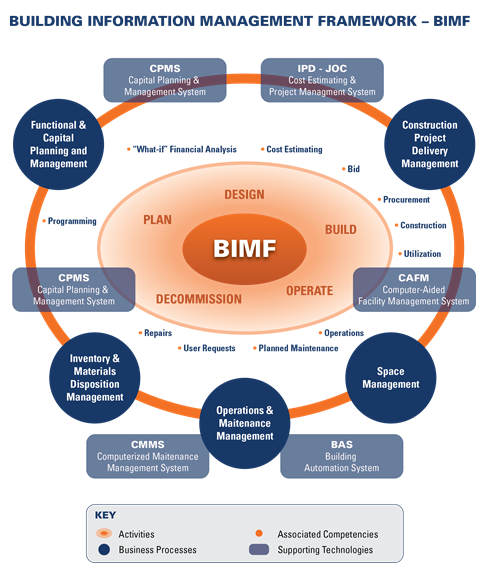

Growing numbers of cost estimators, however, need to work with multiple projects and multiple estimates simultaneously, securely share information on active projects, gain access to localized cost information, and easily locate and reuse historical data. These Owners, Contractors, and AEs are moving to advanced cost estimating and management systems. They are discovering that significantly higher productivity can be gained – as much as 50 percent or more. Furthermore, the collaborative aspects of these sophisticated software systems are aligned with integrated project delivery methods and construction sector movement toward Building Information Modeling (BIM). Cloud computing, a further advancement enabling even higher levels of collaboration and simplified deployment, are also now becoming available.

This paper addresses each of these primary approaches to construction cost estimating and discusses their application. For clarity, products are referenced within each category as follows:

- Spreadsheets – Microsoft Excel

- Electronic Cost Books and Calculators – RSMeans CostWorks

- Cost Estimating and Project Management Software – e4Clicks Project Estimator

- Cloud Cost Estimating – Ceasel

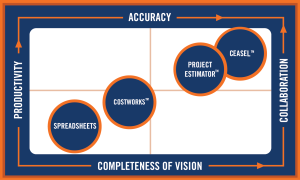

The image below portrays a graphical representation of the increase in accuracy, collaboration, productivity, and project completeness for various cost estimating methods.

Construction estimating involves the estimating of material, labor, equipment, overhead, and contingencies. Spreadsheets, most commonly Microsoft Excel, are used by more estimators for this purpose than any other tool. Spreadsheets have significantly improved cost estimation capabilities and accuracy since the 1980s. Relatively easy to master, spreadsheets provide a means to create and report a construction cost estimate. Cost construction models can also be built within spreadsheets. Productivity improvements result from the ability of Excel to easily handle more of the mundane calculations required.

One problem with spreadsheets, however, is their inherent vulnerability to errors due to data entry, a problem that only increases along with the complexity of an estimate. As the formulae within the spreadsheets become more numerous and complex, errors became exponentially more frequent and costly. [2]

Spreadsheets also do not account for dynamic cost information and associated uncertainties or historical information – all of which have proven to be important variables for many construction projects.

Lastly, and in part due to the issues noted above, collaboration using spreadsheets is problematic, as are transparency and accurate monitoring and reporting. Having multiple people working on the same spreadsheet is not efficient or even workable for larger projects. Thus estimates tend to be created and stored in different locations, making information difficult to accurately retrieve and changes extremely costly to execute. As a result, old data errors are perpetuated, copied over and over again.

Electronic Cost Books and Calculators

As it became apparent that more localized and historical data would be critical to improving the accuracy of construction cost estimates and cost models, organizations instituted a formal process for collecting and storing this information. Individual Owners, Contractors, AEs, and other third parties began to collect this information. RSMeans Cost Data has become North America’s standard for commercial construction cost data including materials, equipment, and labor line items, productivity factors, and assembly and square foot cost information. Localized cost indexes, referred to as the City Cost Index (CCI), are also available.

Based upon the size and type of construction project, estimators soon found that they could improve their productivity and accuracy even further by using standardized reference cost information in combination with spreadsheets. Such reference cost information included RSMeans Cost Data or other reference cost sources, along with cost data architectures such as Construction Specifications Institute (CSI) MasterFormat and UniFormat. However, manually entering in tens, hundreds, or even thousands of cost line items from hardcopy cost books remained tedious and prone to data input errors and errors of omission.

Integration of electronic cost book information directly with a cost calculator was the next logical step. An example of this approach is RSMeans CostWorks product. CostWorks can best be described as an electronic version of RSMeans Cost Books where line items can easily be copied and pasted into spreadsheets. CostWorks also incorporates some limited cost calculation tools moving it even closer to the needs of construction cost estimators. Many inherent data input errors associated with spreadsheets appeared to be mitigated. Other issues remained largely unsolved including: collaboration, data reuse, document management, integration and maintenance of alternative cost data sources, reporting, and the integration of robust construction delivery workflows. To provide easier Internet access to RSMeans Cost Books, RSMeans Online is now being offered in addition to the CostWorks CD-ROM. RSMeans Online enables simplified deployment and a somewhat updated user interface.

Collaborative Cost Estimating Software Solutions

Spreadsheets have proven valuable for single, static estimates of a certain project size, as well as for a media to gather and transfer data sets. Similarly, the integration of electronic cost books with spreadsheets and electronic cost calculators (such as CostWorks/RSMeans Online) are equally valuable for individuals performing a small number of relatively straight forward construction, repair, or renovation estimates (three to five per year).

However, both spreadsheets and electronic cost calculators do not meet the need for collaboration, transparency, document management, and maximized productivity. They also do not provide a capacity to adhere to and report upon specific construction delivery methods and/or contracts such as Job Order Contracting (JOC), Integrated Project Delivery (IPD), Simplified Acquisition of Base Engineering Requirements (SABER), and Indefinite Delivery Indefinite Quantity (IDIQ). Collaborative cost estimating and project management solutions also support today’s need for Adaptive Project Delivery (APD)ä. APD enables Owners, Contactors, and AEs to modify and constantly improve upon construction project delivery processes to meet their individual and changing requirements.

Integrated cost estimating, project management, contract management, and document management software systems have become very popular over the past decade and are exemplified by e4Clicks Project Estimator. e4Clicks Project Estimator incorporates this type of cohesive management in a single application.

e4Clicks Project Estimator allows users to create estimates and manage multiple types of projects and contract methods: JOC, SABER, IPD, Single Award Task Order Contracting (SATOC), Multiple Award Task Order Contract (MATOC), Multiple Award Construction Contract (MACC), Indefinite Delivery/Indefinite Quantity (IDIQ), Performance Oriented Construction Activities (POCA), and Basic Ordering Agreement (BOA). Users can select from enhanced RSMeans electronic cost data, including an exclusive 400,000 line item database with full descriptions and modifiers as well as graphics, diagrams, and specifications, and/or custom/internal cost information or other standard/custom unit price cost books.

Visual estimating and quantity take-off (QTO) are also core components of this type of advanced software. eTakeoffä, included within e4Clicks Project Estimator, stands head and shoulders above other visual estimating solutions, enabling estimators to quickly and precisely visualize requirements and trace electronic drawings to determine quantities for line items within estimates. Drawings can be shared in various formats include Adobe Systems Portable Document Format (PDF). The eTakeoff/4Clicks integration enables users to quickly transfer to e4Clicks Project Estimator.

Visual estimating allows the user to:

- Estimate and pre-bid processes without paper plans.

- Create measurements by tracing upon electronic drawings.

- View plans with powerful zooming and scrolling capabilities.

- Display measurements in an infinite variety of colors and patterns to identify the type of construction and the materials used.

- Total measurements from multiple plan sheets.

Cloud Cost Estimating

Cloud computing enables the next level of collaboration and real-time work with virtually unlimited processing power and storage. Cloud computing applications, such as 4Clicks’ Ceasel, connect people, information, and processes – anytime, anywhere.

Ceasel allows the user to do more with fewer resources, while also improving cost estimating and project delivery outcomes. This is made possible by Ceasel’s ability to enable higher levels of service, economies of scale through shared but secure resources, rapid and flexible deployment, standardization, and the ability for cost estimators, project managers, and procurement professionals to connect and share previously incompatible information.

With Ceasel, the user logs in through a web browser and can immediately build estimates with the best representation of RSMeans Cost Data available, custom data, or a combination of both. Cloud computing technology stores data permanently, keeping a detailed history of changes so work is never lost. Unlike spreadsheets, Ceasel and similar products provide the flexibility for teams to work simultaneously with large databases from any location around the world.

From a deployment perspective, cost estimating software solutions and true cloud cost estimating solutions address the creation of custom parameters, multiple “knowledge bases,” and easily support client-server network or stand-alone system environments.

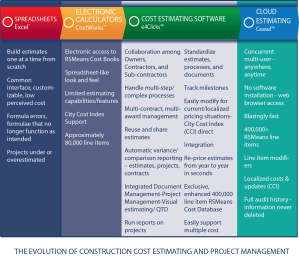

These powerful tools yield superior productivity, accuracy, transparency, collaboration, and information reuse. They are best suited for anyone using RSMeans Cost Data and/or custom cost data for renovation, repair, and sustainability projects, as well as estimators managing tens to hundreds of projects per year. The chart below shows the capabilities deployed by each estimating tool.

Conclusion

Over the past forty years, there have been many initiatives to improve cost estimating to facilitate the delivery of construction projects on time and on budget. Owners, Contractors, and AEs now have multiple methods to select from based upon their needs.

Spreadsheets were a major improvement in the 1980s, followed by formal processes for collecting and harnessing historical information to more accurately project and control costs. Over the past decade, a powerful new capability has been added, collaborative cost estimating and project management software. Within the past two to three years, cloud computing offers yet another advancement in terms of ease of deployment, scalability, and real-time collaboration.

Over the past forty years, there have been many initiatives to improve cost estimating to facilitate the delivery of construction projects on time and on budget. Owners, Contractors, and AEs now have multiple methods to select from based upon their needs.

Spreadsheets were a major improvement in the 1980s, followed by formal processes for collecting and harnessing historical information to more accurately project and control costs. Over the past decade, a powerful new capability has been added, collaborative cost estimating and project management software. Within the past two to three years, cloud computing offers yet another advancement in terms of ease of deployment, scalability, and real-time collaboration.

[1] Christofferson, Jay. “Estimating with Microsoft Excel”, Brigham Young University. Nickols, Robert Duane. “Construction Estimating Using Excel” Lexington Technical Institute, University of Kentucky.

2 Caulkins, Jonathan P., et al. “Do Spreadsheet Errors Lead to Bad Decisions” Carnegie Mellon University.