Defining High Performance Buildings for Operations and Maintenance

Angela Lewis, David Riley, Abbas Elmualim

ABSTRACT

Most practicing facility managers, engineers and building owners, as well as academics and researchers of the built environment have heard of the term high performance building. Some may even be designing, constructing or working in or researching high performance buildings. However, what a high performance building is, especially for operations and maintenance, is still being debated and defined. The aim of this research paper is to synthesize current literature about high performance buildings, with a specific focus on operations and maintenance. In doing so, the paper seeks to further define what a high performance building is, while also hypothesizing that to overcome current challenges to achieve successful operation and maintenance of a high performance building will require practitioners and researchers to collaborate to solve the challenges necessary to successfully operate and maintain high performance buildings. The paper concludes that systems-thinking, for both building systems (heating, ventilating and air-conditioning, lighting and others) and organizational systems, is necessary to achieving successful high performance building operation.

LIST OF ABBREVIATIONS

BAS: Building automation system

BIM: Building information model

CAFM: Computer aided facility management system

CMMS: Computerized maintenance management system

FDD: Fault detection diagnostics

HPB: High performance building

HVAC: Heating, ventilating and air conditioning

IWMS: Integrated work management system

O&M: Operations and maintenance

INTRODUCTION

The operational phase of a commercial building is significantly longer than the design and construction phase of a project. The lifecycle cost of the operational life of a building is about 60 to 85 percent of the total lifecycle cost, where as the design and construction is about five to ten percent. Acquisition, renewal and disposal costs are between five and 35 percent of the total life cycle cost (Christian and Pandeya 1997). When employee salaries and benefits are included in the lifecycle cost, design and construction costs make up only one percent of the lifecycle cost. Operations and maintenance make up 11 percent and employee salaries and benefits make up 88 percent of the lifecycle cost (NIBS 1998).

As the operational phase of a building is longer and more cost intensive, the focus of this research paper is to define what a high performance building is for the operations and maintenance phase of commercial buildings. To date, much of the research work within high performance buildings has focused on design and construction. In order to meet many energy efficiency and sustainability goals, there is a great need to define how current definitions apply to and can inform operations and maintenance of commercial buildings. Within this paper, operations is defined as services necessary to keep equipment and systems operating as designed or at a level that meets the operational goals of the facility management team. Maintenance services are defined as services that help restore equipment or systems to design conditions or to conditions that have been determined to be sufficient for the given project scope. The building systems and equipment focused on within this paper are heating, ventilating and air-conditioning (HVAC) systems, building automation systems (BAS), lighting, renewable energy technologies and software that support these systems, such as computerized maintenance management systems (CMMS), computer aided facility management systems (CAFM) and energy analytics software. To operate a high performance building requires proactive management processes for energy and maintenance.

Within the United States, high performance buildings are a topic of interest to industry, academics, the research community and government. The goal of this paper is to help synthesize current literature and discussions with industry members and researchers from the fields of engineering (HVAC and control systems) and facility management (maintenance management, energy management and IT) to further define high performance building operations and maintenance. The paper first seeks to further define what a high performance building is, and then discusses how to apply the definition through a discussion of technologies, processes and skills needed to operate and maintain high performance buildings. The paper concludes with a discussion of systems thinking, a strategy which the authors hypothesize is important for successful high performance building operation and maintenance.

Defining a High Performance Building

Within both research and industry, the terms high performance building, green building, sustainable buildings, and intelligent buildings are used. Although many would argue that many of these terms are still being defined or refined, this paper suggests that these terms are interrelated. The relationship between these terms is very important to defining high performance building operations and maintenance.

To demonstrate the interrelations and support further refinement of the definitions of high performance, green, sustainable and intelligent buildings definitions from several industry, government and research sources are synthesized below.

As defined by the United States Energy Independence and Security Act 2007, a high performance building is:

“A building that integrates and optimizes on a lifecycle basis all major high performance attributes, including energy [and water] conservation, environment, safety, security, durability, accessibility, cost-benefit, productivity, sustainability, functionality, and operational considerations” (Energy Independence and Security Act 2007 401 PL 110-140).

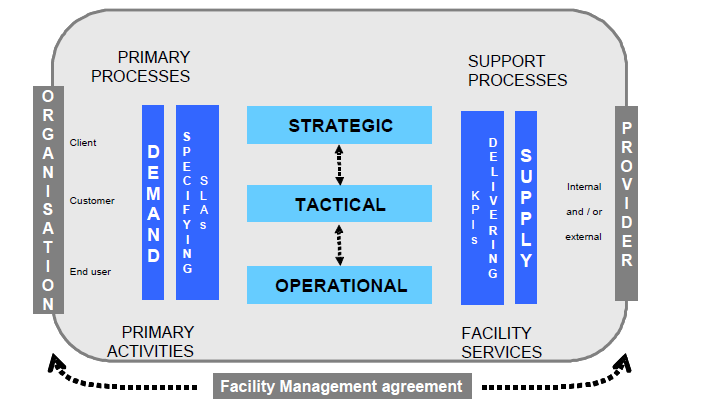

The definition of an intelligent building is similar to the definition of a high performance building. However, intelligent buildings emphasize the need for integration and application of technology. As stated by Elmualim (2009) there is a myriad of definitions for intelligent buildings, none of which are scientific. In an absence of such a scientific definition, six (ALwaer and Clements-Croome 2010; CABA 2008; Elmualim 2009; Finley et al 1991; Himanen 2004; Robathan 1996) were compared and contrasted to define an intelligent building within this paper, resulting in the following definition: An intelligent building is a building that integrates people, process and technology in an efficient and sustainable manner through the use of high levels of integrated technology, including but not limited to HVAC, plumbing, electrical, renewable energy systems and sources, information technology, control systems and management software to provide a safe, healthy and productive environment for building occupants that adapts quickly to change at the lowest possible lifecycle cost.

Comparing and contrasting the three definitions for green buildings (CABA 2008; US EPA 2010; LEED Reference Guide 2001), the definitions for green and intelligent buildings are more similar to each other than each is to the definition of a high performance building. Synthesizing the definition from the three sources, a green building is a building that is designed, constructed and operated to minimize environmental impacts and maximize resource efficiency while also balancing cultural and community sensitivity.

CABA (2008) suggest that the concepts of intelligent and green buildings should converge. CABA suggests that the convergence of green and intelligent building concepts should be called bright green. Within the convergence, topics that are both green and intelligent (bright green) include: energy management, asset management, space utilization, integrated design, sustainability, renewable energy, indoor environmental quality and green building purchasing structures (CABA 2008).

As the term sustainability has also been used within many discussions of HPB, intelligent and green, it is also important to define sustainability here. Many built environment researchers, industry practitioners and professional organization use the definition or a variation on the definition commonly recognized as the Brundtland Report, Our Common Future (1987) as the definition for sustainability: “development that meets the needs of the present, without compromising the ability of future generations to meet their own needs.” As some may argue that this definition is more philosophical than practical, within industry this definition has often applied considering the triple bottom line, balancing environmental, economic and social goals (Hodges 2009; Lewis et al 2009).

Reviewing the definitions of high performance, intelligent, sustainability and green buildings, there are many similarities. The authors hypothesize that these definitions will continue to be debated and refined by researchers and practitioners. It is also hypothesized that facility managers and building owners will use different variations on the definitions, depending on goals and priorities. In order to apply definitions and theoretical concepts, it is important to emphasize that successful operations and maintenance of a HPB requires integration and knowledge about HPB technologies, processes that support HPB and people with skills to effectively utilize HPB technologies. Thus, technologies, tools, processes and skills necessary for high performance building operation and maintenance are discussed below.

High Performance Building Technologies

High performance buildings have more complex mechanical, lighting and control systems, many which are far from common place within the industry. Some of the heating ventilating and air conditioning systems (HVAC) within HPB include, but are not limited to: radiant heating and cooling, dedicated outdoor air systems (DOAS), chilled beams and advanced control sequences programmed in building automation systems (BAS). Advanced control strategies include, but are not limited to morning warm-up, fault detection diagnostics, the use of thermal mass for heating or cooling and demand response. Additionally, HPB are more likely have software to monitor and benchmark energy efficiency and operational performance. Thus, the number of meters and sensors linked to BAS is often greater than a non-HPB.

Lighting systems often included within HPB include, but are not limited to automated lighting control, such as motion sensor lighting, integration of daylighting and electronic lighting, automated shading, and light emitting diodes (LEDs).

Renewable energy technologies are also common to HPB, including solar, wind and geothermal systems. Solar systems include photovoltaic arrays and solar thermal systems. Photovoltaic arrays can be connected to inverters to invert direct current (DC) from the photovoltaic arrays to alternating current (AC), which is used for most commercial building applications. Alternately, a less common application is to connect photovoltaic panels to a battery bank or devices that use DC current, such as LEDs or DC powered kitchen appliances.

Sophisticated technologies often found within HPB can cause some challenges to building operators and facility managers. Challenges can occur when building operators, technicians and facility managers have not had the opportunity to learn about HPB technologies, especially what makes HPB technologies unique.

-

There are many new technologies that design and consulting engineers, contractors and facility managers are not familiar with. Often, it is challenging to find the time and/or resources necessary to understand the benefits of the technologies, how they work and the cost of implementing them.

-

Many industry members seek out demonstration or pilot projects to determine the risk of designing, installing, operating or managing new technologies in an effort to reduce risk. Although there is general interest to support many new technologies, risk is often a barrier, as most designers, contractors and owners generally do not want to be the first to design, install, manage or operate a new technology.

-

The design, installation and operation of many HPBs require a systems-thinking and integrated approach. However, neither systems-thinking nor integration are currently standard industry practice (McCaffer 2010).

-

The industry lacks a feedback loop for facility managers and building operators to communicate what systems and equipment worked as designed and where further improvement is necessary (McCaffer 2010; Arditi and Nawakorawit 1999). A feedback loop for HPB is especially important as many HPB technologies are not standard practice and there are many, often conflicting opinions about what systems and equipment should be used in HPB.

High Performance Building Processes

The installation of highly energy efficient equipment and systems is only the foundation for achieving efficient high performance operation. The processes used to operate and maintain buildings have an even larger cost and environmental impact than the design and construction process. In fact, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) suggests that a building with good operations and maintenance practices that is poorly designed will often out perform a well-designed building with poor operations and maintenance practices (ASHRAE 2009). HPB processes should include, but are not limited to the use of benchmarking for decision making, retro and/or re-commissioning, the use of proactive maintenance techniques, the use of rating and certification systems, systems thinking and balancing comfort and energy efficiency.

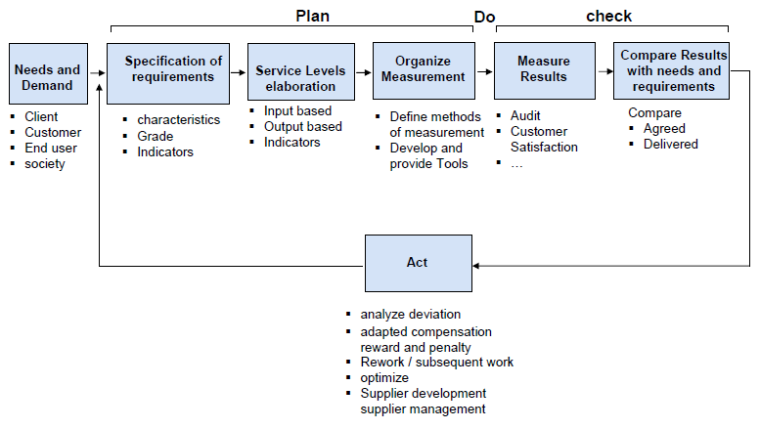

Benchmarking is the process of comparing measurements against a standard, average or best in the business with the purpose of improvement and movement towards best practices. Benchmarking must be stakeholder driven and focus on improvement, rather than the status quo. Benchmarking can be done once or continually (Atkin and Brooks 2000; Wireman 2004; Stapenhust 2009). However, greater benefits are likely to result from continual benchmarking. Although benchmarking is not a new practice to the facility management and building operations community, the use of benchmarking to set improvement goals is not currently standard industry practice. Benchmarking can be used to help in decision making and meet sustainability goals. More specifically, benchmarking is beneficial because it can be used to (NREL 2003):

-

Determine how well a building is performing

-

Set targets for improvement

-

Facilitate assessment of property value

-

Gain recognition

Commissioning is the process of verifying that a building and its systems and equipment are operating according to the owner’s project requirements. Retro-commissioning is the process of commissioning a facility that was not previously commissioned (ASHRAE Guideline 0 2005). Re-commissioning is the process of commissioning a building that had been commissioned before (ASHRAE Guideline 0 2005) . Retro-commissioning and re-commissioning are important in order to keep buildings operating efficiently. Over time, building functions change, equipment wears and sensors drift out of calibration. The benefits of retro- and re-commissioning are well documented in both the research and trade literature. For example, Claridge et al. (1996) finds that building energy consumption can be decreased by as much as 50 percent through retro-commissioning. Mills et al. (2005) find that “commissioning is one of the most cost-effective means of improving energy efficiency in commercial buildings.”

Maintenance is the day-to-day activities required to preserve, retain or restore equipment and systems to the original condition or to a condition that the equipment can be effectively used for this intended purpose (APPA 2002; FMpedia 2010; WBDG 2009; Moubray 1997). Proactive maintenance includes preventive, predictive and reliability-centered maintenance. Preventive maintenance is a form of maintenance scheduled over time (Ring 2008; ASHRAE 2003). The main function of preventive maintenance is to keep equipment running reliably and safely, not to increase efficiency (Ring 2008). The principal objectives of preventive maintenance are durability, reliability, efficiency and safety (ASHRAE 1991). Predictive maintenance is form of maintenance based on equipment condition. Predictive maintenance uses non-destructive testing, chemical analysis, vibration and noise monitoring and visual inspection to determine equipment conditions and access when maintenance should be performed (ASHRAE 1991). The philosophy of reliability centered maintenance combines preventive and predictive maintenance by balancing cost and the impact of equipment downtime on the facility using relationships about equipment failure rates (Moubray 1997).

Maintenance is a very important, but often overlooked part of HPB. For example, Wood (2005) claims that building maintenance is under researched. Maintenance is needed to keep equipment operating efficiently. Without maintenance, overtime belts begin to slip, filters are filled with particulates, equipment begins to vibrate and bearings need greasing – all of these have the potential to decrease energy efficiency, while increasing utility costs. In many cases, maintenance is one of the first costs to be cut from a facility manager’s budget because building owners and financial decision makers often do not understand the benefits of maintenance (Pugh 2010).

Although basic economic theory states the value of a dollar (unit of currency) today is greater than the value of the same dollar (unit of currency) tomorrow, there can be significant cost savings from investing in proactive maintenance. Table 1 summarizes the annual cost savings (US dollars) for proactive maintenance practices in units of US dollars per horsepower.

Table 1: Cost Savings for Use of Proactive Maintenance, Compared to Reactive Maintenance (Piotrowski 2001)

| |

Cost [$/HP] |

Savings [$/HP] |

| Reactive |

$18/HP |

—- |

| Preventive |

$13/HP |

$5/HP |

| Predictive |

$9/HP |

$9/HP |

| Reliability Centered |

$/HP |

$12/HP |

It is suggested that successful operation of a HPB requires proactive maintenance management practices. To date, there is a great need for more maintenance related research to advance proactive maintenance management practices. For example, Wood (2005) claims that building maintenance is under-researched.

Building rating and certification systems for existing buildings, such as the United States Green Building Council (USGBC) Leadership in Energy and Environmental Design for Existing Buildings Operation and Maintenance (LEED –EBOM), Green Globes Continual Improvement Assessment for Existing Buildings, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) BuildingEQ or the Building Owners and Managers Association (BOMA) Building Environmental Standards (BOMA BESt) can also help to inform HPB process improvements. Many rating and certification systems have a checklist or set of credits or points that can be used to help set goals. Setting goals and working to achieve a certification or rating can help to hold teams accountable to meet the goals set, while also providing opportunities for recognition.

Systems-thinking is a process of understanding how the parts of an organization or building fit together to make a whole. Systems-thinking at the organizational level is the integration and understanding of the people that make up the organization, as well as the values, structure, processes, policies, regulations and supervision within an organization (El-Homsi and Slutsky 2010). As stated by El-Homsi and Slutsky (2010), systems-thinking requires goal setting, development, incentives, communication, reviews, rewards and accountability.

Systems- thinking, when applied to building systems is the understanding of how all the components of a larger system interact with each other to meet the needs of the building occupant. For example, using a systems thinking approach, when a technician is dispatched to respond to an occupant’s complaint that a room is too cold, the technician will consider how the adjustment made to the diffuser or damper within the terminal box will impact the entire cooling system, often including the chillers and the cooling towers. As a second, more broad example, systems-thinking is also necessary during major equipment and system replacements and upgrades – if more efficient lamps are installed in an office area, the cooling load will be reduced, which will reduce the load on the chiller. Depending on the operational parameters of the chiller, reduction of the amount of heat generated from the more efficient lamps and other factors, the chiller controls may need to be readjusted so that the chiller operates efficiently under new space conditions.

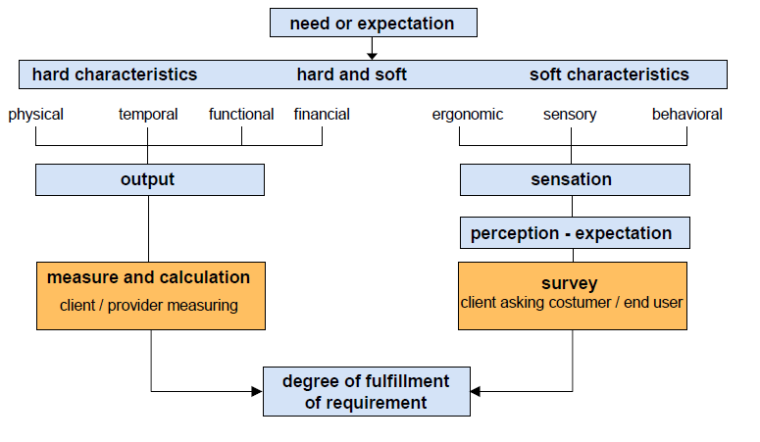

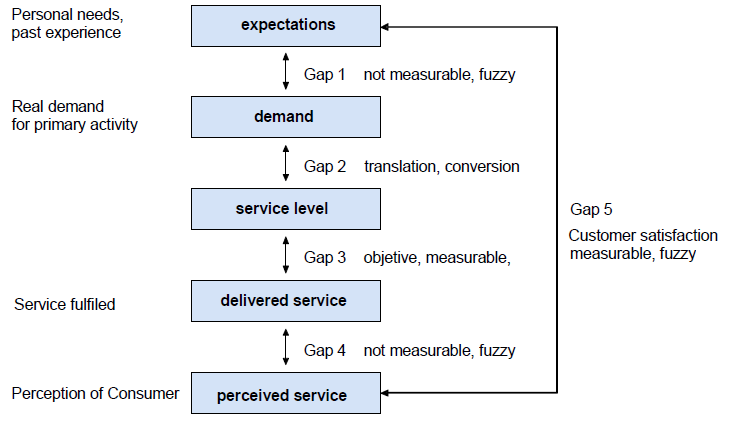

Finally, the function of the building, such as occupant comfort and providing a productive, safe and healthy indoor environment cannot be scarified to save energy or achieve sustainability goals. Tom (2008) finds that keeping a building at a comfortable temperature and relative humidity is important for occupant satisfaction. To keep building occupants comfortable while operating equipment efficiently requires a balance between energy consumption and comfort. Although many facility managers measure energy, it is often more difficult to measure comfort. Comfort is difficult to measure because it is subjective and depends on individual perceptions (Tom 2008). To determine if building occupants are comfortable, two basic approaches can be used:

As shown, there are many different management processes that are used to keep a HPB operating efficiently. Although many of these processes are documented within industry and research literature, implementing these and other HPB processes within an existing facility management organization can be challenging. Some reasons process implementation is difficult include:

-

Facility management departments are often large and perform a diverse number of tasks to support the primary functions of the organization.

-

If it is necessary to adopt a new or refine an existing policy or procedure, employees of an organization can be resistant to change, as there can be a mind-set of “we’ve always don tit this way.” Overcoming the challenge requires effective change management strategies and diplomacy. Additionally, members of the facility management team must be educated about the reasons and value of the change.

-

Less research has been done within the areas of operations and maintenance of existing buildings, compared to the design and construction of buildings. Therefore, there are fewer industry standards that facility managers can use as a foundation to create organizational specific standards and polices.

-

Existing job functions may need to be rewritten to accommodate new policies and procedures.

Tools to Manage High Performance Building Processes

Software is needed to manage the data and information necessary to make decisions about how to operate and maintain a high performance building. Software used and discussed within this paper includes computerized maintenance management systems (CMMS), computer aided facility management systems (CAFM), integrated work management systems (IWMS), enterprise resource systems (ERP), building automation systems (BAS), energy information systems and energy analytics software. Elmualim (2009) suggests that intelligent building management [software] is about having a common user interface and integration. A common user interface and integration are key parts of HPB software because they support systems-thinking. As previously discussed, a HPB cannot be operated or maintained without considering both the impact of decisions on the entire organization and the impact on the technical systems. A common interface allows data from multiple sources to be viewed from one screen. Interoperability is the process that supports the concept of viewing data from many sources from one interface. The topic of interoperability will be discussed in later in the paper.

There are two platforms for O&M management software, local server-based and software as a service (SaaS). Local server-based software requires that the software be located on servers at the facility. Local server-based software provides facility managers with the opportunity to customize and configure the software to meet specific organizational needs. It also requires in-house staff or contracted staff to maintain the software and perform any necessary upgrades. Software as a service can eliminate the need for in-house staff to maintain and upgrade the software, as the software is maintained and upgraded by the service provider. However, opportunities for configuration and customization may be less available, as the SaaS model is generally has a standardized Internet-based user interface.

Within the United States market, there are three basic types of software for asset, space and maintenance management: computerized maintenance management systems (CMMS), computer-aided facility management (CAFM) and integrated workplace management systems (IWMS). The core function of a computerized maintenance management system is to manage information related to maintenance, including but not limited to work orders, asset histories, parts inventories, maintenance personnel management and the calculation of maintenance metrics. The core function of a computer-aided facility management system is primarily space management, used to identify and manage assets. An integrated workplace management system combines the functionality of both a CAFM and a CMMS, and sometimes may also include functionality more commonly associated with an enterprise resource planning system (ERP). An ERP can be used across an entire organization to manage all types of information, including human resources, procurement and the functions of CAFM and CMMS.

Although IWMS, CAFM and CMMS software are becoming more commonly used (Sapp 2008), successfully implementing these systems can be challenging. Berger (2009) found that more than 50 percent of CMMS implementations fail – or are underutilized. Lewis (2010) found that part of the reason for underutilization was a lack of understanding of the importance of accurate asset inventories and maintenance records. As a result, the most commonly used CMMS modules were those that did not require asset data to be populated into the system, including the work order generator, work order tracking and the storage of maintenance records.

A building automation system (BAS) is a control system that uses digital control (analog and binary signals) to monitor, control and manage mechanical (HVAC) and electrical systems within buildings. The core function of a BAS is to maintain indoor environmental conditions (temperature and relative humidity) within a building during specified hours of operation. A BAS also monitors equipment performance and failures, and can provide notifications of unsatisfactory operating conditions in the form of alarms to the building operator. There are several other acronyms that are also used to describe and define a BAS, including energy management system (EMS) and energy management and control system (EMCS).

Although not the primary function, a BAS can also be used to monitor, trend and benchmark building energy consumption. In order for a BAS to be used as an energy performance monitoring or benchmarking tool, sub-meters and equipment and system level sensors must be installed, a server to store trend data must be available and a report generator must be configured (Lewis 2010).

Three other products that can be used for energy performance monitoring and benchmarking are enterprise resource planning (ERP) systems, energy analytics software and energy information systems. These three products are similar to each other as they all aggregate data from meters, sub-meters and sensors to quantify building energy consumption in units that are useful to the end user and often use a dashboard to displays the information electrically. Specific information to include and how to display the information on the dashboard are currently being debated (Shadpour 2010). These products can range from free and publically available, such as Portfolio Manager ENERGY STAR (Roskoski et al 2009) to very complex and potentially expensive, such as a customized application integrated with the ERP for the entire organization.

Interoperability and Integration

Interoperability and integration are key needs for true implementation HPB O&M technologies and practices. Interoperability is the ability to manage and communicate electronic data between different software products and systems (Gallaher et al 2004). Integration is the synchronization of two or more electronic products or systems. The lack of interoperability and integration within current software is illustrated by Gallaher et al (2004): $10.5 billion (US dollars) is lost annually due to inoperability of software within the operations phase of buildings. The use of building information modeling (BIM) promises to part of the solution to reducing interoperability and integration challenges for facility management. Building information modeling is a structured dataset that describes a building (NBIM 2007), the data within a BIM often includes a three-dimensional computer model and a database (Fallon 2008).

There are currently many efforts underway regarding BIM and interoperability that show promise to help reduce the annual loss reported by Gallaher et al (2004). A full review of these efforts is beyond the scope of this paper. Readers interested in BIM are encouraged to view the buildingSMARTalliance website: www.buildingsmartalliance.org/

People: Skills Needed to Operate and Maintain High Performance Buildings

Trained facility managers, building operators and technicians are a critical part of HPB O&M. Without properly trained staff, it will be difficult for the energy efficiency or HPB goals of any building to be met. Facility managers and technicians must be knowledgeable of the technologies and processes previously discussed. From a management approach using systems-thinking, facility managers must understand how HPB knowledge aligns with the core competencies of facility management. The International Facility Management Association (IFMA) currently defines nine facility management core competencies (IFMA 2010):

-

Operations and maintenance

-

Real estate

-

Human and environmental factors

-

Planning and project management

-

Leadership and management

-

Finance

-

Quality assessment and innovation

-

Communication

-

Technology

The most recent IFMA Global Job Task Analysis determined that two additional core competencies should be added: environmental stewardship and sustainability and human and environmental emergency preparedness and business continuity. From the list of competencies, there are many ways HPB O&M impact the daily responsibilities of facility managers.

The specific skill set of building operators and technicians is less clearly defined. Similarly to facility managers, building operators and technicians are often required to have a very diverse skill set. One example that summarizes this brief skill set of technicians is the North American Technician Excellence (NATE) Knowledge Areas of Technician Excellence (KATE) (NATE 2010). This list of knowledge areas was determined through a job task analysis and defines core installation and core services areas. Core installation and core service areas are generally categorized as air-side systems and fuel source (oil or gas) and refrigeration.

Two areas that are under defined within the NATE KATE is building automation system (BAS) and systems-thinking skills for operators and technicians, especially for medium and large commercial buildings. A recently completed National Science Foundation (NSF) report, “Current Situation and Trends in Buildings and Facility Operations” (Ehrlich et al 2010) finds that there are few formal training and educational opportunities BAS technicians. Although a few programs exist through community colleges and trade union apprenticeship programs, the most common form of training for BAS technicians is on-the-job training. On-the-job training is necessary, and an important part of all jobs. However, as technologies in buildings become more automated, Ehrlich et al. conclude that on-the-job training will not be sufficient to meet the needs of technicians who will operate and maintain HPB. On-the-job training does not provide sufficient opportunity to gain an understanding of how systems work or general problem solving skills.

Defining a Systems-Thinking Approach to HPB

To truly operate and maintain a high performance building requires the synthesis of people, process and technology using a systems-thinking approach. As demonstrated from the discussion above, this requires the extraction of knowledge from multiple areas of expertise, including but not limited to HVAC and control systems, energy and maintenance management, software and IT systems and competencies of managers and technicians. In order to achieve the goals set by both government and private organizations, it will be necessary to transition from commonly used silo-thinking to systems-thinking. This will require both researchers and industry practitioners to use non-traditional communication paths. For researchers, especially academic researchers, this may mean an increased breadth of a research project to use a more holistic approach that includes analysis of the impacts of the technicians on the people and processes – not just the technologies. For industry practitioners, this may mean a more diverse understanding foundational knowledge of multiple subsets within his/her discipline and/or determining how to more effectively share industry challenges with researchers who often have the skills necessary to solve complex problems and time to focus on research projects.

Conclusions

The purpose of this article was to define and synthesize what a HPB is for O&M. In order for HPB technologies to truly be high performance requires the implementation proactive practices, especially for energy and maintenance management. Finally, maintaining and operating a HPB requires properly trained personnel, including facility managers, building operators and technicians. In doing so, the authors sought to provide insight about interdependencies and relationships between technologies, processes and people necessary for high performance building operations and maintenance. In order to operate and maintain a HPB will require systems-thinking. Systems-thinking must be applied to building systems (HVAC, lighting, etc) and to organizational processes (such as maintenance management, technician training and strategic planning).

It is through an integrated, systems-thinking approach that lifecycle costs of operation and maintenance and environmental emissions will be reduced and resource consumption as a result of building operation decreases. As the result of the synthesis completed for this paper, the following areas of future research are recommended:

-

Data management and metric standardization for energy performance and benchmarking

-

Maintenance management process development and data management strategies

-

Interoperability schemas and use cases for building information modeling

-

Effective training methods for HPB technologies and processes

ACKNOWLEDGEMENTS

Paul Ehrlich and Jeffery Seewald of the Building Intelligence Group for helping to inform the thinking that helped develop the foundation for this article. This article is part of a larger research project, A Framework for Improving Building Operating Decisions. Funding that supported the foundational stages the research was provided from a National Science Foundation Graduate Research Fellowship, an ASHRAE Graduate Student Grant-In Aid Award and the Partnership for Achieving Construction Excellence at The Pennsylvania State University.

REFERENCES

ALWaer, H.; D.J. Clements-Croome. (2010). “Key performance indicators (KPIs) and priority setting in using the multi-attribute approach for assessing sustainable intelligent buildings.” Building and Environment 45(2010): 799-807.

APPA (2002), Maintenance Staffing Guidelines for Educational Facilities, Alexandria, VA.

Arditi, D. and Nawakorawit, M, (1999), “Issues in building maintenance: property managers’

perspective”, Journal of Architectural Engineering, Vol. 5 No. 4, pp. 117-32.

ASHRAE (2009), The Decision-Maker’s Guide to Energy Efficiency in Existing Buildings, Atlanta, GA, ASHRAE.

ASHRAE (2005), ASHRAE Guideline 0-2005 The Commissioning Process, American Society of Heating, Refrigerating and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (2003), HVAC Design Manual for Hospitals and Clinics, Atlanta, GA.

ASHRAE (1991), ASHRAE Terminology of HVAC&R, American Society of Heating, Ventilating and Air-Conditioning Engineers, Atlanta, GA.

Atkin, B. and A. Brooks (2000), Total Facilities Management, Oxford, Blackwell Publishing.

Berger, D. (2009). “2009 CMMS/EAM Review: Power Up a Winner,” available at: www.plantservices.com/articles/2009/066.html

Brundtland, (1987), Our Common Future, The World Commission on Environment and Development. Clays Ltd., Bungay, Suffok, Great Britain.

CABA, (2008), Bright Green Buildings Convergence of Green and Intelligent Buildings, available at: www.caba.org/brightgreen

Christian, J. and A. Pandeya, (1997), Cost predictions of facilities. Journal of Management in Engineering 13(1):52-61.

Claridge, D., M. Liu, et al. (1996), Implementation of Continuous Commissioning in the Texas LoanSTAR Program: Can you Achieve 150% of Estimated Retrofit Savings?: Revisited, Proceedings of the 1996 ACEEE Summer Study (August).

Ehrlich, P.; J. Seewald; A. Lewis; R. Kupritz, (2010), Current Situation and Trends In Buildings and Facility Operations, Research Supporting National Science Foundation Project “Educating Technicians for Building Automation and Sustainability,” Grant No. 0802595.

El-Homsi, A.; J. Slutsky, (2010), Corporate Sigma Optimizing the Health of Your Company with Systems Thinking. CRC Press, Boca Raton.

Elmualim, A., (2009), Application of computer-aided facilities management (CAFM) for intelligent buildings operation. Facilities 27(11/12): 421-428.

Fallon, K., (2008), Interoperability: Critical to Achieving BIM Benefits, by K. Fallon.

Finley, M.R.; Karakura, A. and Nbogni, R., (1991),“Survey of intelligent building concepts,” IEEE Communication Magazine.

FMpedia, (2010), IFMA Foundation. Definition of maintenance, available at: gsishare.com/ifma/FMpedia/gv.aspx, (accessed February 18, 2010).

Gallaher, M.P.; A.C. O’Conner; J.L. Dettbarn Jr. and L.T. Gilday, (2004), Cost Analysis of Inadequate Interoperability in the US Capital Facilities Industry, National Institute of Standards and Technology, Gaithersburg, Maryland.

Himanen, M., (2004), “The intelligence of intelligent buildings,” in Clements-Croome, D. (Ed.), Intelligent Buildings: Design, Management and Operation, Thomas Telford, London.

Hodges, C., (2009), Getting Started. IFMA Foundation Sustainability How-To Guide Series. available at: www.ifmafoundation.org/programs/sustain_wp.cfm (accessed June 2, 2010).

IFMA (2010), International Facility Management Competency Areas. available at: www.ifma.org/learning/fm_credentials/competencies.cfm (accessed July 7, 2010).

LEED Reference Guide, (2001), Version 2.0, United States Green Building Council.

Lewis, A., (2010), Designing for Energy Efficient Operations and Maintenance, Engineered Systems, August 2010.

Lewis, A., (2010), Quantifying Energy Performance beyond the Use of Energy Bills

FMJ, October 2010.

Lewis, A.; K. Cacciloa; R.B. Dennill, (2009), Sustainability in the Food Service Environment, IFMA Foundation Sustainability How-To Guide Series, available at: www.ifmafoundation.org/programs/sustain_wp.cfm (Accessed July 9, 2010).

Mills, E., N. Bourassa, et al. (2005), “The Cost-Effectiveness of Commissioning.” HPAC Engineering, October 2005.

McCaffer, R., (2010), Innovation: Imagination and Knowledge. Sixth International Conference in Innovation in Architecture, Engineering and Construction. Keynote. University Park, PA June 9 -11, 2010.

Moubray, J. (1997), Reliability-centered maintenance. Second edition. Industrial Press, Inc., New York.

NATE (2010). North American Technician Excellence, Knowledge Areas of Technician Excellence, available at: www.natex.org/HVAC_HVACR/cert_kates.html (Accessed July 11, 2010).

NREL, (2003), High Performance Commercial Building Systems – PIER Building Energy Performance Program, Final Program Presentation.

NBIM, (2007), National BIM Standard, National Institute of Building Sciences.

NIBS, (1998), Excellence in Facility Management. National Institute of Building Sciences,

Facility Maintenance and Operations Committee, 5350-1.

Piotrowski, J., (2001), Pro-Active Maintenance for Pumps, Archives, February 2001, Pump-Zone.com www.maintenanceworld.com (Accessed August 21, 2008).

Pugh, R. (2010), Operations, Maintenance and Commissioning. First Thursdays Seminar, Federal Energy Management Program (FEMP), Webinar July 1, 2010.

Robathan, P. (1996). Building Performance. Facilities Management Theory and Practice. K. Alexander. London, E & FN Spon.

Ring, P. (2008), “Maintenance in Moderation is the Most Efficient Method.” Tradeline Inc. (January).

Roskoski, M.; L. Gilmer; G. Hughel. (2009), IFMA Foundation Sustainability How-To Guide Series, EPA’s ENERGY STAR Portfolio Manager, www.ifmafoundation.org/programs/sustain_wp.cfm.

Sapp, D. (2008), “Computerized Maintenance Management Systems (CMMS),” available at www.wbdg.org/om/cmms.php (accessed August 29, 2008).

Shadpour, F., (2010), Facilities Dashboards: What Do You Want to See?, Forum #6. ASHRAE Annual Conference, June 26- 30, 2010, Albuquerque, NM.

Stapenhust, T., (2009), The Benchmarking Book, Oxford Butterworth-Heinemann.

Tom, S., (2008), “Managing Energy and Comfort.” ASHRAE Journal 50(6): 18-20,22,24,26.

US EPA, (2010), Basic Information, Definition of Green Building, available at: www.epa.gov/greenbuilding/pubs/about.htm

Wireman, T., (2004), Benchmarking Best Practices in Maintenance Management. New York, Industrial Press

WBDG, (2009), Whole Building Design Guide, Facilities Operations & Maintenance, available at: www.wbdg.org/om/om.php (accessed February 18, 2010).

Wood, B., (2005). “Innovative building maintenance.” Conference Proceedings of The Queensland University of Technology Research Week International Conference, 4-8 July 2005 Brisbane, Australia, pp 601-7.

About the Authors

Angela Lewis, PE, LEED AP, is a PhD Candidate at the University of Reading within the Department of Construction Management and Engineering. Lewis is also a Facility Management Consultant/High Performance Buildings Engineer with the Building Intelligence Group.

David is an Associate Professor at Penn State in the Department of Architectural Engineering specializing in green building methods and sustainable technologies. David earned his PhD in Architectural Engineering from Penn State. David currently leads a research program focused on the integration of mechanical and electrical energy systems with distributed renewable energy sources. His research areas include the integration of green building technologies and high performance design process modeling. As the Director of Penn State Center for Sustainability, he develops programs that engage students in the pursuit of sustainability challenges on the Penn State campus as well as external communities.

Abbas is a Senior Lecturer at the University of Reading and Coordinator of the Sustainable Design, Construction and FM research group. He has a PhD in Sustainability and Renewable Energy from the University of Reading. Currently Dr. Elmualim leads several industry funded collaborative projects. Abbas’s research focuses on the development of integrative approaches to design, construction and facilities management. He is particularly interested in sustainability and digital technologies from a broad socio-technical systems perspective. The research approach seeks to combine engineering research methodologies with those derived from the social sciences.

This work is licensed under a Creative Commons Attribution 3.0 License.

ISSN: 2150-3303